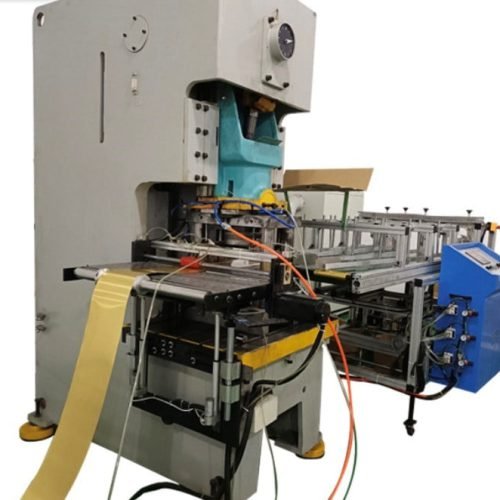

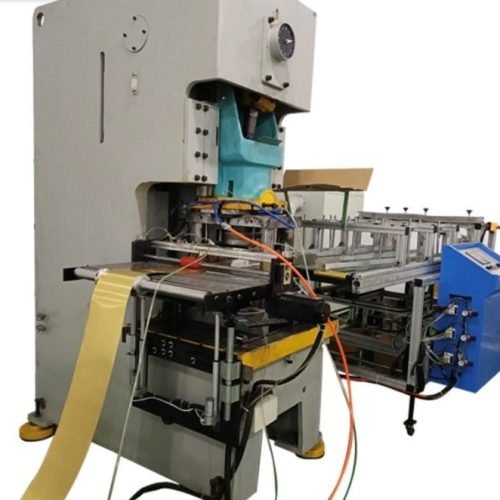

T-shirt Bags Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

1. BG-500*2 Full Auto. Super High Speed Double Lanes Plastic T-shirt Bags Making Machine with EPC and Lay-on-roll

The BG-500 Full Auto. Super High Speed Double Lanes Plastic T-shirt Bags Making Machine is an automatic bag-making machine with efficient production capacity with PE film material, suitable for making both printed bags and non-printed bags. This machine is equipped with the double-lane system, making the machine capable of producing up to 600 pieces of T-shirt bags per minute. This machine is highly suitable for commercial and retail applications.

Technical Specification of T-shirt Bags Making Machine

| S.N | Component | Specification |

| 1. | Frame Structure |

|

| 2. | Unwinder System |

|

| 3. | Photocell Sensor |

|

| 4. | Material back feeding |

|

| 5. | Main Motor |

|

| 6. | Material feeding motors |

|

| 7. | Photocell Tracking for Printed Bags |

|

| 8. | Heat sealing and cutting technology |

|

| 9. | Material Block detect |

|

| 10. | Touch Screen Operation |

|

| 11. | Digital Thermometer |

|

| 12. | Static Eliminators |

|

| 13. | Cutting and Punching Air Supply |

|

| 14. | Punching Machine Control |

|

Spare Parts for T-Shirt Bags Machine

| Spare Part | Quantity |

| Heater | 2 pcs |

| Teflon Tape | 1 pcs |

| Heating switch | 1 pcs |

| Button | 1 pcs |

| Oil Can | 1 pcs |

| Spring | Some pcs |

| Tool box | 1 pcs |

2. BG-500*2 Full Automatic High Speed Double Lanes Plastic T-shirt Bags Making Machine (3Phase 380V 50HZ)

BG-500*2 Full Automatic High-Speed Double Lanes T-Shirt Plastic Bag Making Machine (3Phase 380V 50HZ) is specially designed for producing plastic T-shirt bags using various film materials like HDPE, LDPE, PLA, PBAT, and other biodegradable films. Featuring double lanes operation, it allows simultaneous production of two lines, efficiently handling both printed and non-printed bags with high precision and speed.

Main parameters of the BG-500*2 (3Phase 380V 50HZ) T-shirt plastic bags making machine

| S.N | Parameters | Specifications |

| 1. | Bag making width | 180-450 mm * 2 lines |

| 2. | Bag making length | 320-650 mm |

| 3. | Max bag-making speed | 250-300 pcs/min x2 lines |

| 4. | Thickness | 0.008-0.05 mm |

| 5. | Cutting blade length | 460 mm |

| 6. | Rubber roller length | 490 mm |

| 7. | Power Consumption | Approx. 16 kW |

| 8. | Main motor(sealing and cutting) | 1.5 kW with 1.5 kW inverter control |

| 9. | Feeding motor | 400 x 2 sets with double inverter control |

| 10. | Static Eliminator | 250W 16kV |

| 11. | Air pressure | Required 0.5-2 MPa |

| 12. | Conveyor Belt Size(Width x Length) | 1030mm x 2900mm |

| 13. | Required Gas Pressure | 10HP |

| 14. | Power Supply | 380V, 50Hz, 3 Phase |

| 15. | Machine Dimension(L*W*H) | 6.2m * 1.7m * 1.8m |

| 16 | Machine Weight | Approx. 2500 Kgs |

Technical Specification of BG-500*2 (3Phase 380V 50HZ) T-shirt Bags Making Machine

| S.N | Component | Specification |

| 1. | Frame Structure |

|

| 2. | Material Roll Loading |

|

| 3. | Material feeding system |

|

| 4. | Main Motor |

|

| 5. | Material feeding motors |

|

| 6. | Photocell Tracking Sensor |

|

| 7. | Heat sealing and cutting technology |

|

| 8. | Production process |

|

| 9. | Control System |

|

| 10. | Digital Temperature Control |

|

| 11. | Static Eliminators |

|

| 12. | Air tank for cutting and punching |

|

| 13. | Inverter Control |

|

Main parameters of the BG-500*2 (3Phase 380V 50HZ) T-shirt bags making machine

| S.N | Parameters | Specifications |

| 1. | Max bag-making width | 450 mm * 2 lines |

| 2. | Max bag-making length | 700mm |

| 3. | Max bag-making speed | 250-300 pcs/min x2 lines |

| 4. | Thickness | 0.01–0.05 mm |

| 5. | Rubber roller length | 490 mm |

| 6. | Power Consumption | Approx. 16 kW |

| 7. | Main motor(sealing and cutting) | 1.5 kW with 1.5 kW inverter control |

| 8. | Feeding motor | 400 x 2 sets with double inverter control |

| 9 | Static Eliminator | 250W 16kV |

| 10. | Air pressure | Required 0.5-2 MPa |

| 11. | Punching Air Cylinder | 5T * 2 pcs |

| 12. | Conveyor Belt Size(Width x Length) | 1030mm x 2900mm |

| 13. | Required Gas Pressure | 10HP |

| 14. | Power Supply | 380V, 50Hz, 3 Phase |

| 15. | Machine Dimension(L*W*H) | 5.8m * 1.7m * 1.8m |

| 16 | Machine Weight | Approx. 2000 Kgs |

Spare Parts for BG-500*2 (3Phase 380V 50HZ)T-Shirt Bags Machine

| Spare Part | Quantity |

| Heater | 1 pcs |

| Teflon Tape | 1 pcs |

| Temperature Controller | 1 pcs |

| Heating Switch | 1 pcs |

| Button | 1 pcs |

| Breater | 1 pcs |

| Oil Gun | 1 pcs |

| Spring | Some Pcs |

| Spanner | Some pcs |

| Tool Box | 1 pcs |

3. BG-E500*2 Full Auto. Super High Speed Double Lanes Plastic T-shirt Bags Making Machine (1P 220V 50HZ)

BG-E500*2 Full Auto Super High-Speed Double Lanes Plastic T-shirt Bags Making Machine (1P 220V 50HZ) is designed for efficient production of PE (HDPE/LDPE/LLDPE) T-shirt bags using advanced heat sealing and heat cutting technology. It supports both printed and natural color bags, with double lane operation for simultaneous high-speed production. Equipped with a pneumatic cylinder for easy material roll lifting and an integrated material storage system, the machine ensures stable, precise, and continuous bag-making performance.

Technical Specification of BG-E500*2 (1P 220V 50HZ) T-shirt Bags Making Machine

| S.N | Component | Specification |

| 1. | Frame Structure |

|

| 2. | Unwinder System |

|

| 3. | Front feeding |

|

| 4. | Cutting knife |

|

| 5. | Heating system |

|

| 6. | Material feeding motors |

|

| 7. | Photocell Tracking Eyes |

|

| 8. | Length Control System |

|

| 9. | Auto Counting and Alarm System |

|

| 10. | Temperature control system |

|

| 11. | Static Eliminators |

|

| 12. | PLC and Touch Screen |

|

| 13. | Air supply system for cutting and punching |

|

| 14. | Punching Machine Control |

|

Main parameters of the BG-E500*2 (1P 220V 50HZ) T-shirt bags making machine

| S.N | Parameters | Specifications |

| 1. | Max bag-making width | 450 mm * 2 lines |

| 2. | Max bag-making length | 650mm * 2 lines |

| 3. | Max bag-making speed | 180-230 pcs/min x2 lines |

| 4. | Thickness | 0.008-0.015 mm |

| 5 | Cutting blade length | 460 mm |

| 6. | Rubber roller length | 490 mm |

| 7. | Power Supply | 380V 50hZ 3 Phase |

| 6. | Power Consumption | Approx. 7 kW |

| 7. | Main motor(sealing and cutting) | 1.5 kW with 1.5 kW inverter control |

| 8. | Feeding motor | 400 x 2 sets with |

| 9 | Static Eliminator | 250W 16kV |

| 10. | Air pressure | Required 0.5-2 MPa |

| 11. | Punching Air Cylinder | 5T * 2 pcs |

| 12. | Conveyor Belt Size(Width x Length) | 1030mm x 2900mm |

| 13. | Machine Dimension(L*W*H) | 5.5m * 1.65m * 1.6m |

| 14. | Machine Weight | Approx. 2500 Kgs |

Spare Parts for BG-E500*2 (1P 220V 50HZ) T-Shirt Bags Machine

| Spare Part | Quantity |

| Heater | 1 pcs |

| Teflon Tape | 1 pcs |

| Temperature Controller | 1 pcs |

| Heating Switch | 1 pcs |

| Button | 1 pcs |

| Breaker | 1 pcs |

| Oil Gun | 1 pcs |

| Spring | Some Pcs |

| Spanner | Some pcs |

| Tool Box | 1 pcs |

FAQs on T-shirt Bag Making Machine

What is a plastic T-shirt bag making machine?

T-shirt bag machine is an automatic machine that produces plastic bags using various materials like PE film, HDPE, LDPE, PLA, PBAT, etc.

What products does a T-shirt bag making machine produce?

A T-shirt bag making machine produces plastic shopping bags that are commonly used in retail shops for packing t-shirts.

Can the machine make both printed and non-printed bags?

Yes, our T-shirt bag-making machine can make both printed and non-printed bags according to the user’s requirements.

What are the power requirements for a T-shirt bag-making machine?

Typical models require a 380V, 50Hz, 3-phase or 220V, 50Hz, single-phase power supply, depending on the machine configuration.

Is the machine fully automatic?

Yes, the t-shirt bag making machine is fully automatic, as it performs sealing, cutting, punching, and stacking automatically.

Can recycled plastic film be used?

Yes, recycled material can be processed as a film for t-shirt bag making production with proper quality control.

What determines the bag size?

The size of the bag is determined by the bag width, length, and handle size, which are all adjustable through settings.

What is the average production speed?

Speed depends on the film thickness, but it supports high-volume production, which is good for small- to medium-sized businesses.

Is this machine suitable for long production hours?

Yes, the machine is built for long production hours with constant and uniform processing for optimal efficiency.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province