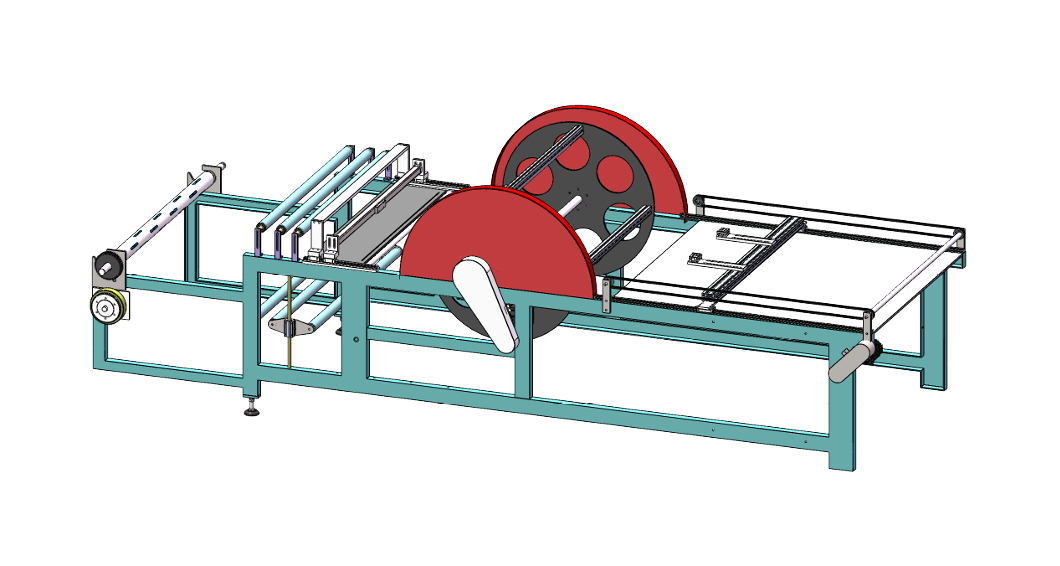

Paper rolls to sheet feeding machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

A sheet feeding machine is an advanced equipment that is designed for high-speed folding of materials such as aluminum foil, Polyethylene (PE), and Polypropylene (PP). These materials are practically used for packaging, printing, and processing of foods and in various industries of manufacturing.

This machine is used for advanced technology with ensuring simple operations, automated controls, as well it offering secure production. Moreover, this sheet feeding machine also offers user requirements for the rapid folding of various materials, allowing industries to meet high production demands while maintaining product consistency and quality.

Technical Parameters

| Model | DZ-1500 |

|---|---|

| Power Supply | AC 380V |

| Production Capacity | 120pcs/min |

| Dimensions | 3250mm (L) * 3320mm (W) * 2600mm (H) |

| Operating Temperature | 5 degrees celcius–40 degree celcius |

Structural Composition

The sheet feeding machine mainly consists of the following parts:

- Electrical cabinet: It houses the electronic control units, power supply modules, and safety systems that govern machine operations.

- Main unwinding structure: Responsible for unwinding sheet rolls smoothly and without tension irregularities.

- Folding and stacking structure: Ensure accurate folding of materials and arrange them neatly into stacks for easy handling.

- Automatic winding structure: Provides automatic winding of excess or processed materials, reducing manual handling.

Furthermore, these systematic figures of this equipment provide stable operations, reduced wear, tear, and minimal maintenance requirements.

| Sheet feeding machine |

| Items | Specification |

| 1) Machine model | BF- 1500 |

| 2) Power | 6 kw |

| 3) Weight | 1500kg |

| 4) Speed | 120 pcs/min |

| 5) Equipment | BF202515-26 |

| 6) Voltage | AC380V |

| 7) Date | February 2025 |

| 8) Address | No. 13, Weizijiao Middle Road, Yuepu Street, Jinping Area, Shantou City, Guangdong Province, China |

| 9) Phone number | +8618957999107 |

Features

This equipment is designed with advanced characteristics that help in enhancing productivity and user experiences:

- User-friendly interface, along with parameter setting, tends to be convenient and fast

- Fault self-diagnosis function, fault display at a glance

- Positioning stop function, no sticking knife, no waste envelope

- The work is more reliable as the transmission system is easy, and the maintenance of the sheet feeding machine is more convenient.

- It defines the cutting length automatically.

- Improves the long-term reliability as this machine provides a smooth mechanism with minimal vibrations.

- It reduces downtime and maintenance costs.

- It is easy to clean, and service is reliable.

Operating Instructions

Pre-start Preparation

- Needed to check whether the overall parts of the equipment are installed or not.

- It is recommended to check if the power supply is compatible and meets the equipment’s needs.

- Also, the points of the lubrication have been lubricated or not.

Start-Up operation

- Equipment is activated by pressing the power switch.

- The Operating parameters can be set via the touch screen interface.

- To begin the operation, press the start button.

Shut-down procedure

- The equipment operations can be halted by pressing the stop button.

- A power switch is needed to turn off.

- If there are any residual materials, it is advised to remove them and clean the surface.

Daily maintenance and care

Daily Maintenance

- After each day of work, it is necessary to clean the surface and interior of the equipment.

- On time, it is needed to tighten all fasteners and remove looseness.

- It is necessary to inspect the lubrication of the transmission parts daily and add lubricating oil as needed.

Regular Maintenance

- To check whether the equipment has aged or been damaged, it is necessary to inspect the electrical wiring monthly.

- Along with a transmission system and control parts, conduct an inspection of the equipment quarterly.

- Worn parts need to be replaced annually.

Safety precautions

- While the equipment is operating, into the moving parts do not insert hands or any other objects into it.

- To disassemble or repair the equipment, only qualified professionals are authorized.

- To ensure against any kind of electrical leakage accidents, it is necessary to properly ground the equipment.

- It is crucial to stop the machine immediately for an inspection if any irregularities are detected, such as unusual noises, overheating, and others.

- Additionally, when cleaning or checking the mechanism, remember to disconnect the main power supply to safeguard yourself from any hazards.

FAQS on Paper rolls for the sheet feeding machine:

1. What types of materials can this machine process?

This machine is to process and handle aluminium foil, Polyethylene (PE), and Polypropylene (PP), which are commonly used in packaging, printing, and in the processing of food industries.

2. Does this machine have an automated control system or not?

Yes, it does have an automated control system, as it features a user-friendly touch screen interface along with an automated parameter system.

3. How much power does this machine require?

This equipment operates on AC of 380V with a power consumption of 6 kW.

4. What safety measures are in place for operators?

For electrical safety, this machine has a grounding capability that stops in an emergency, and most importantly, it requires a licensed professional for maintenance or repair.

5. What maintenance does this machine require?

This machine requires daily cleaning, adding lubricating oil if needed, regular checkups, inspecting wiring monthly, and the replacement of worn parts.

6. Is the sheet size adjustable?

Yes, the length and width of the paper rolls for the sheet-feeding machine can be adjusted.

7. What industries use this machine?

The paper roll to sheet feeding machine is used by industries that do packaging, printing, and paper converting business.

8. Does it support high-speed operation?

Yes, the paper rolls to sheet feeding machine is designed for continuous and uniform output.

9. Is operator training required?

This machine can be operated by anyone that has gone through basic machine training.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province