APPM-0001 Paper Plate Making Machines

|

Payment Terms |

L/C, T/T at sight |

Power |

9000W |

|---|---|

|

Voltage |

380V 50Hz |

|

Stroke |

|

|

Area |

3000Lx1700Wx1700H (mm) |

Product Description

About APPM-0001 Automatic Plate Machines

Paper Plate Making Machines is an automatic machine that can produce paper plates on an industrial/commercial scale. Various advanced systems equipped in the machine make it easier and convenient to operate. It ensures the maximum safety of the user while operating the machine.

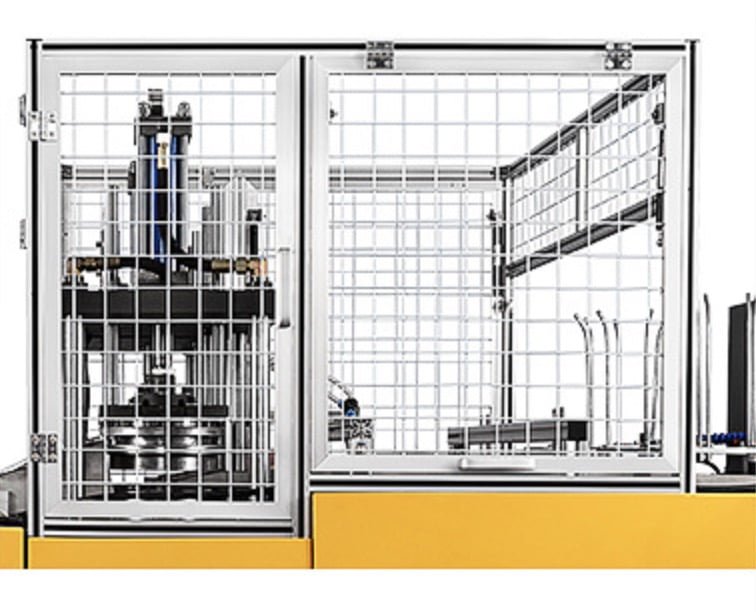

Machine Appearance:

Main Technical Parameters

| S.N | Parameter | Description |

| 1 | Paper Size |

|

| 2 | Production Speed |

|

| 3 | Air Pressure |

|

| 4 | Raw Material |

|

| 5 | Power Voltage | |

| 6 | Total Power |

|

| 7 | Weight |

|

| 8 | Package Size |

|

Machine Features and Advantages

| S.N | Parameters | Descriptions |

| 1 | Simple Operation |

|

| 2 | Automatic Collection device |

|

| 3 | New Product |

|

| 4 | Multiple Shapes |

|

| 5 |

|

|

| 6 | Support customization |

|

More Features

| S.N | Parameters | Description |

| 1 | PLC Control System

|

|

| 2 | Smart Touchscreen

|

|

| 3 | Sensor- fault self-check

|

|

| 4 | Electrohydraulic System

|

|

| 5 | Statistical Collection

|

|

| 6 | Conveyor System

|

|

| 7 | Plate forming mold

|

|

| 8 | Safety Protective Cover

|

|

| 9 | Multi-layer suction cup

|

|

Output

FAQs

1. What is a paper plate making machine?

A paper plate making machine is an automated system used to produce disposable paper plates by feeding raw paper sheets, heating and forming them, cutting the plate shape, and counting and stacking finished products in one continuous process.

2. What types of paper plates can this machine make?

Depending on the mold used, these machines can produce various plate types, including round plates, square plates, and other special shapes with customization.

3. What materials can be used with the paper plate making machine?

The machines typically work with base paper from 100 to 600 gsm, cardboard, ivory board, and aluminum‑foil laminated paper.

4. How fast can a paper plate making machine produce plates?

Typical fully automatic machines like the double workplace model can produce around 70–120 plates per minute depending on the material and machine configuration.

5. Is the paper plate machine easy to operate?

Yes. These machines usually include a PLC control panel with a touchscreen for simple parameter setting and adjustments, making them easier to operate than manual machines.

6. Does the machine have safety or automatic features?

Many machines include features such as automatic feeding, stable paper guiding to avoid jams, automatic counting and collection, and built‑in safety stops if a jam or error is detected.

7. What size of paper blanks do these machines accept?

For example, a common model can accept blank sheets up to approximately 300×300 mm, suitable for making plates from about 5 inches up to 11 inches in size.

8. What warranty or after‑sales support is provided?

Machines typically come with a one‑year warranty covering manufacturing defects in mechanical and electrical parts. Some suppliers also offer optional training and after‑sales service support.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province