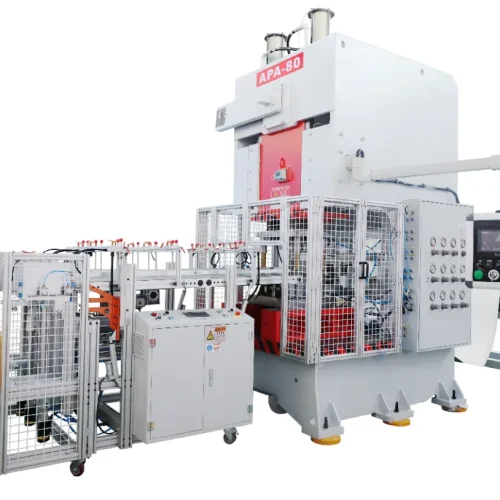

PCPM-0001 Paper Cup Packaging Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

3000W |

|---|---|

|

Voltage |

220 |

|

Stroke |

12-75 times/min |

|

Area |

5600*1500*1750 |

Product Description

About Paper Cup Packaging Machine

A top-performing PCPM-0001 Paper Cup Packaging Machine allows direct integration into paper cup manufacturing processes. Extensive useable components paired with modern technology features enable users to operate this paper cup packaging machine easily while ensuring quick and reliable operation and convenient repairs. This PCPM-0001 Paper Cup Packaging Machine provides customized intelligent control features while providing reliability and meets diverse industrial requirements for expansion and quality optimization.

Appearance

Main Features of Paper Cup Packaging Machine

1. Simple operation and stable performance

2. Easy maintenance with durable machine components

3. Smart touch screen LCD display control

4. The high hardness alloy material end sealing cutter provides this system with its important closing component.

5. Fast heat conduction and deformation resistance

6. Ribbon tracking hot print coder

7. The automatic roll film shaping system works along with other features.

8. PID dual temperature control system

9. The control system incorporates a Smart PLC circuit board which enables programming operations through the board.

10. Customizable machine configurations

Technical Specifications

| Specification | Details |

|---|---|

| Control System | Smart LCD Touch Screen + PLC |

| Sealing Mechanism | High Hardness Alloy Cutter |

| Temperature Control | PID Dual Control with Real-time Display |

| Printing System | Ribbon Tracking Hot Coder |

Advanced Features

1. Smart Touch Screen Control

The PCPM-0001 Paper packing machine incorporates an LCD touch-type display screen which has replaced its traditional mechanical button panels. Contact input signals operate through the smart screen which provides users with an intuitive along with efficient method of control. Real-time system control together with monitoring enables smooth and easy management of the packaging process for packing machinery.

2. High Hardness End Sealing Cutter Device

A high-hardness alloy material forms the end sealing cutter which operates with fast heat conduction capabilities and outstanding durability qualities. A highly durable cutter device can resist continuous use and delivers prolonged stable sealing functions required for quality packaging maintenance.

4. Ribbon Tracking Coder

Ribbon tracking functionality of the built-in coder system permits accurate hot printing with selectable color shading options. The device includes an adaptable loading and unloading type mechanism to print precise information accurately on different packaging substrates while enabling production tracking functions.

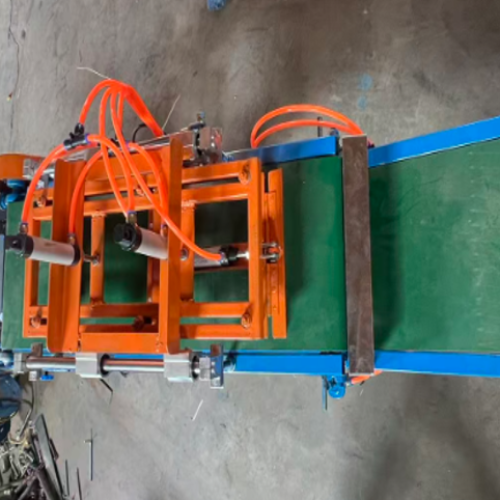

5. Automatic Roll Film into Bag Shape

Using automatic controls the paper packing machine shapes roll film into neat and durable bags while needing little operator assistance. The durable nature of produced bags along with their prolonged life ensures proper presentation and protective wrapping functions for paper cups.

6. PID Dual Temperature Control System

The dual temperature control operates based on a differential antecedent algorithm which works through valve position control. The device shows and controls packaging film temperature in real time to create accurate seals that result in stable package outcomes.

7. Smart PLC Circuit Board

A smart PLC circuit board on the PCPM-0001 Paper Cup Packaging Machine allows programmers to control its main circuits. Delivery of crucial control elements through central monitoring functions enables advanced machine intelligence and operational safety and easy maintenance operations.

Final Pictures

Frequently Asked Questions (FAQs)

1. What is a paper cup packaging machine?

The paper cup packaging machine provides automated packaging services by placing completed paper cups into either film or bag containers.

2. What is the paper cup manufacturing process?

The complete process starts from converting paper rolls into cups through heating and sealing while curling the rim before final packaging by a paper cup packing machine.

3. Is a paper cup microwave-safe?

The microwave safety of paper cups depends on manufacturer labelling which indicates their compatibility for the microwave. Heating paper cups with plastic or wax linings will cause both destruction to their shape and potentially dangerous substances to escape into food or liquid.

4. Paper cup machine how much?

Prices range from automation degree and options. Semi-automatic or manual machines are cheaper while automatic machines with smart touch control, like the PCPM-0001, are more expensive but offer higher productivity.

5. What is the total cost of a paper cup manufacturing machine?

The equipment’s pricing depends on the level of automation features incorporated with the device. A paper cup machine’s price depends on whether it operates manually or semi-automatically however it becomes more expensive when featuring advanced features such as PCPM-0001’s smart touch control and delivers superior productivity results.

6. Does the machine allow packing different cup sizes during operation?

Yes. The machine PCPM-0001 provides customizable options for processing different paper cup dimensions and different packaging specifications.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province