Paper and Non-Woven Fabric Cutting Machine With 4-rolls feeding

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

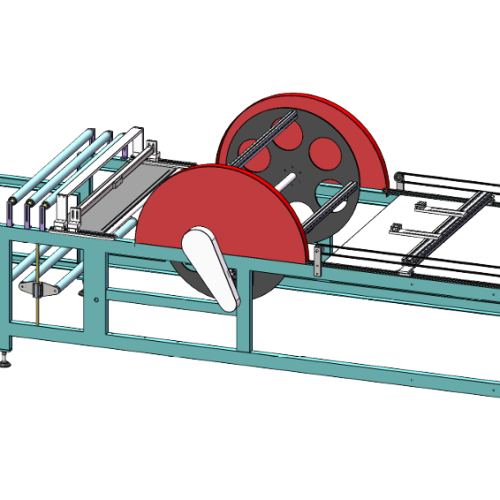

The ZGS-1400 Paper and Non-Woven Fabric Cutting Machine with 4-Roll Feeding System is designed for transverse cutting of non-woven fabric, paper, and other packaging roll materials. This Paper and Non-Woven Fabric Cutting Machine is equipped with a computer control system that supports automatic length setting, automatic counting, sound and light alarms, and high-precision operation. This design supports both Paper cutting machine as well as Fabric Cutting Machine with a compact structure, modern design, and a high level of automation, making it essential equipment for cutting roll-based sheet materials.

This model is composed of four core components supporting the Paper Cutting Machine and the Fabric Cutting Machine, all of which are indispensable:

- Iron plate fuselage

- Double transmission system

- Cutting tool holder

- Cutting blade

Main Technical Specifications of Paper and Non-Woven Fabric Cutting Machine

| Specification | Details |

| Effective Cutting Width | BS-1400mm |

| Effective cutting thickness | 50-130mm |

| Machine Power | 12 KW |

| Machine weight | 3000 KG |

| Cutting Speed | 40-50 cuts per minute |

| Output Capacity | 160-200 meters per minute (1-meter cut, 4 rolls) |

Detailed configuration parameters

| NO. | Component | Specification/Description |

| 1. | Cutter Motor

|

AC Motor (1 unit), 2.2 KW, equipped with a 6-stage brake motor. The brake motor ensures safety protection by preventing blade sliding after a power failure, reducing the risk of hand injury. |

| 2. | Front Feeding Motor | Servo Motor (1 unit), 3.2 KW. Provides high feeding precision and strong power output. |

| 3. | Rear Feeding Motor | AC Motors (4 units), 1.5 KW each. Compared to DC motors, AC motors provide stronger feeding power, better stability, and longer lifespan when controlled by inverters. |

| 4. | Frequency Converter | 5 sets installed for precise speed and power control. |

| 5. | Cutting Method | Cold cutting |

| 6. | Tool holder | Thickened casting tool holder with knife-type structure and precision guide rail up-and-down transmission. Manufactured using a CNC machining center. Weight is 3 times heavier than ordinary knife holders, offering stronger cutting ability and better thickness accuracy. Dual-side guideway transmission reduces adjustment frequency and simplifies maintenance. |

| 7. | Cutting Knife | One set of imported high-speed steel cutting knives made from SKH-9 material. More durable and wear-resistant than SKH-2 alloy steel, with longer service life. |

| 8. | Computer Control System | 7-inch PLC computer system, unified programming, and centralized control. |

| 9. | Double CAM Drive System | Double CAM double-drive system, CAM diameter 180 mm. Driven by a synchronous belt and chain. More stable and powerful compared to single-drive systems commonly used in the market. |

| 10. | Low Voltage Electrical Components | 1 completer set, brand: CHINT |

| 11. | Rubber Roller System | Type III wear-resistant pre-feeding rubber rollers 85 mm (2 pcs); rear feeding rubber rollers 80 mm (8 pcs). More wear-resistant and faster feeding speed compared to standard 70 mm rollers. |

| 12. | Passive Aluminium Rollers | Oxidized aluminum rollers, diameter 52 mm. Do not turn black over time, and do not damage materials. Durable and long-lasting. |

| 13. | Storage Swing Arm Device | 4 sets of mechanical swing arm storage devices. |

| 14. | Safety Light Grid | Safety grating is installed on both the paper cutting machine and the fabric cutting machine sides of the tool holder. The machine stops automatically when hands approach the blade, ensuring operator safety. |

| 15. | Receiving Platform | Automatic lifting receiving platform with a maximum stacking height of 600 mm. |

| 16. | Tagging System | Supports hundreds of tag settings through the computer system for accurate marking and identification. |

| 17. | Feeding Method | Manual feeding using an air expansion shaft with magnetic powder (4sets). |

| 18. | Paper and Non-Woven Fabric Cutting Machine Structure | Integrated 12 mm thick iron plate body with an 8-channel steel structure for the storage section. No welding design ensures higher stability and resistance to deformation. |

| 19. | Shutdown Memory | The machine supports shutdown recording for operational continuity. |

| 20. | Surface Structure | Integrated 12 mm thick iron plate body with an 8-channel steel structure for the storage section. No welding design ensures higher stability and resistance to deformation. |

| 21. | Machine color | Beige, white, and red |

| 22. | Voltage | 220 V |

| 23. | Automatic Tension Controller | The Paper and Non-Woven Fabric Cutting Machine has 4 sets installed. Automatically adjusts tension according to roll diameter. Stops when material ends, allowing smooth continuation of subsequent material. |

|

QUOTATION |

|||||

|---|---|---|---|---|---|

| Customer Name: | Quotation Date: January 12, 2026 | ||||

| No. | Product Name | Model | Quantity | Unit Price (Yuan) | Total Amount (Yuan) |

| 1. | High-Speed Cutting Machine | Model 1400 | 1 | ||

Notes:

|

Conclusion

The Paper and Non-Woven Fabric Cutting Machine with 4-Roll Feeding is a fast, precise, and highly automated solution for cutting roll-based materials. With strong safety features, stable structure, and intelligent PLC control, it delivers reliable performance, high output efficiency, and long-term operational stability for industrial production needs.

FAQs

What materials can this cutting machine handle?

It is suitable for non-woven fabric, paper, and other roll-based packaging materials.

How many rolls can be fed at one time?

The machine supports 4-roll simultaneous feeding, increasing productivity and output efficiency.

Is the machine safe for operators?

Yes. It includes safety light grids, brake motors, and automatic shutdown features to prevent accidents.

Can cutting length and quantity be set automatically?

Yes. The PLC computer control system allows automatic length setting, counting, tagging, and shutdown memory.

What industries commonly use this machine?

It is widely used in packaging, medical supplies, hygiene products, and non-woven fabric processing industries.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province