PA900 Side Seal Bag Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

11000W |

|---|---|

|

Voltage |

220 |

|

Stroke |

120 ~200 times/min |

|

Area |

L5500×W3200×H1300mm |

Product Description

About Side Seal Bag Making Machine

A Side Seal Bag Making Machine is a high-tech industrial machine used to produce plastic or laminated bags with rigid side seals. The machine is commonly used in the packaging business for the production of courier bags, shopping bags, self-adhesive bags, and other specialty-order packaging materials.

Appearance

How It Works:

Material Unwinding: It starts with a 1600 mm wide magnetic powder brake with automatic edge guide for simple material feeding.

Folding & Cutting: The unwinder comes with a triangle folder for folding the material, and side and center cutters slice the film into individual bags.

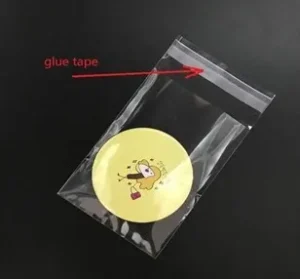

Gluing & Sealing: The machine has a lip-cutting blade to glue the glue tape and an horizontal welding bar to seal the upper surface of the bag.

Hot Cutting & Feeding: Hot cutting bar powered by a 2 kW AC motor and 2.2 kW drive with high accuracy for cutting the material is aided by a 500 W AC motor and photoelectric eye for precise positioning.

Other Features: The equipment is provided with round hole puncher, adhesive tape applicator, bottom gusset former, and printed mark track follow photocell to allow precise cutting, sealing, and finishing.

Final Output: A servo motor controlled feed-out system ensures neat bag handling for stacking and collection.

Components Included:

- 1600 mm magnetic powder brake & automatic edge guide wide unwinder

- Triangle folder for use with unwinder, for example, as a second unwinder for colored film band

- Side cutter for cutting the large tube film

- Middle cutter for PE tubes, meaning two smaller bags can be created from one PE tube

- Lip-cutting blade for glueing glue tape

- Horizontal welding bar to seal the bag mouth

- Bag mouth folding device

- 2 kW AC motor & 2.2 kW driven hot cutting bar

- 500 W AC motor & photoelectric tracking back film feeding system

- Printed mark tracking photocell for accurate cutting and printing alignment

- 6 mm round hole puncher

- Adhesive tape attaching device

- Bottom gusset former to form the bag bottom

- Servo motor-driven feed-out system for Bag handling convenience

Who Can Use This Machine?

- Packaging manufacturers

- E-commerce businesses (for postal and courier bags)

- Supermarket & retail suppliers

- Manufacturers of industrial packaging

Our products are designed for high-speed automatic production, thus reducing the labor cost with precision, efficiency, and strength.

Options:

- Butterfly hanger hole puncher: USD 300/set

- Ultrasonic welding: USD 700/set

- PP side hot cutting bar: USD 260/set

- Automatic bag stacker & conveyor: USD 1,200

Trade Terms:

- Packing: Simple packing with film wrapping

- Installation Cost: Not included

- Delivery Time: 30 days

- Payment Terms:

- 30% advance payment

- 70% before shipment (after testing at the seller’s factory)

- A testing video will be provided for confirmation before shipment

Main Features of Side Seal Bag Making Machine

Application Material: Sealable plastic film such as PP, PE, OPP, BOPP, etc.

Main drive: A.C motor + Inverter for smooth and stable operation.

Feeding motors:

- Equipped with one servo motor and driver for speed and bag length adjustment.

- Equipped with one AC motor and photoelectrical eye for back film feeding.

- With one set of dancing roller for back feeding tension adjustment.

- Automatic synchronization between the main motor and back-feeding motor.

Bag making type: Produces side sealing bags asper specifications.

Computer Control: Fully computer-controlled.

Unwinding Section:

- One unwinding station to handle a 1600 mm wide film roll before folding.

- Magnetic powder brake system for unwinding.

- Automatic edge guide.

Bag Making Section

- This bag making machine can cut maximum two lines at once.

- Hot cutting blade for plain side cutting.

- Belt conveyor for bags collection, driven by a C motor.

- Equipped with static-remover bars.

- Automatic heating control for hot cutting blades.

- Single photocell for printed bag alignment.

- Equipped with bottom gusset former.

- Equipped with adhesive tape attaching device.

- Equipped with central cutting blades and side cutting.

- Equipped with round hole puncher

- Equipped with bag mouth folding and bag mouth horizontal welding.

Main Parameters

| Cutting width (for bag length) | Max.800 MM x 1 line, or 400 mm x 2 lines |

| Cutting length (for bag width) | No limit, just adjusted in the computer |

| Thickness of material (single sheet) | 8 microns ~ 100 microns |

| Bag making line | 1 |

| Bag making precision | ± 0.2mm |

| Bag-making Speed | 120 ~200 bags/minute/line |

| Power | 11 KW/220 V, 50 HZ |

| Machine Weight | 1600 KG |

| Overall Dimensions (MM) | L5500×W3200×H1300mm |

Main configuration

| Item No. | Description | Quantity | Brand name | Origin |

| 1 | DC motor | 1 pc | Youda | Ruian, China |

| 2 | AC main motor | 1 pc | Lichao | Shanghai, China |

| 3 | Servo motor | 1 pc | Xuncheng | Wuhan, China |

| 4 | Inverter | 1 pc | Kowo | Shenzhen, China |

| 5 | Temperature controller | 3 pc | Yatai | Shanghai, China |

| 6 | Micron computer | 1 pc | Xuncheng | Wuxi, China |

| 7 | Tracking photocell | 1 pc | BAIDE | Wuxi, China |

| 8 | Display screen | 1 pc | Zhongxing | China |

| 9 | Power relay | 4 pcs | Chint | China |

| 10 | Air breaker | 12 pcs | Chint | China |

| 11 | Power buttons | 12 pcs | Chint | China |

| 12 | Power switches | 6 pcs | Chint | China |

Results

Optional Feature: Butterfly Hanger Puncher

Included Feature: 6mm Round Hole Puncher

Included Feature: Hot cutting bar for plain cutting side

Optional Feature: Ultrasonic welder for the cross-dot sealing

Included Feature: Hot cutting bar for plain cutting side

Included Feature: Glue tape putting device

Looking for a high quality machines and products? Our Leading Machine Supply Company based in China, offers effective, high-speed, and customized options to match your production needs.

FAQs for Side Seal Bag Making Machine

- Is side seal bag making machine easy to use?

Yes! The touch screen control panel guarantees easy use with minimal manual adjustments. - Can it be customized?

Yes! You can include other features like hanger hole punchers, round hole punchers, bottom gussets, and printed bag tracking. - Can it produce bags of different sizes?

Yes! The length and width of the bag can be adjusted for different uses. - How does it deliver accuracy in cutting and sealing?

It is fitted with photoelectric sensors and servo motors that guarantee all the adjustments to accurate cutting and sealing. - What about warranty and support?

Each maker offers a one-year warranty and lifetime technical assistance and availability of spare parts. - What electrical and site requirements are needed to install this machine?

The machine typically requires a stable 220 V/380 V three‑phase power supply, proper grounding, enough workspace for feeding and stacking, and a level factory floor for safe installation and operation. - What training and after‑sales support are provided during installation?

Most suppliers offer installation assistance and operator training, either on-site or online, to ensure proper setup. After that, ongoing technical support, spare parts, and maintenance guidance are usually provided.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province