Napkin Packing Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

15000W |

|---|---|

|

Voltage |

380 |

|

Stroke |

|

|

Area |

6524×4055×1797(mm) |

Product Description

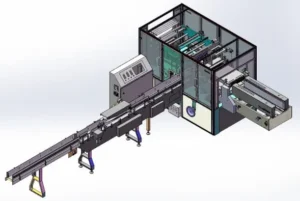

About Napkin Packing Machine

Our Napkin Packing Machine is built to provide efficient, stable and high-precision packaging. It has a small design and simple use. It provides automatic calculation and saving of parameters to increase the efficiency of the adjustment process.

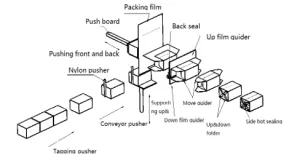

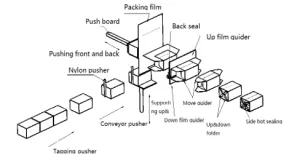

This paper napkin packing machine uses spring rotary cutters to extend the cutter’s life and achieve smooth and precise cutting. The three dimensional wrapping, folding and edge sealing system makes the packaging more beautiful and more durable. The advanced anti-empty packaging technology avoids material loss, and the electronic handwheel provides precise control.

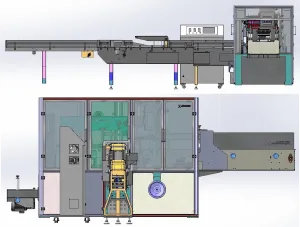

1. Appearance

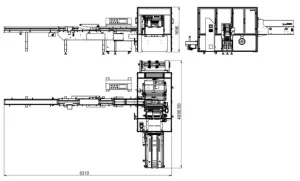

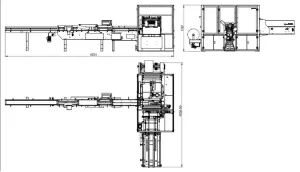

2. Three views of the machine

Figure 1 Dimensions (Unit mm)

3. Technical data

Main technical parameters

1. After replacement of individual parts, packaging specifications fit range L * W * H (mm): Length120—40 Width 100—200mm Height 30—150mm

2. Packing material: CPP (Double-sided heat sealing film):

Heat sealing Film thickness: 0.04mm;

Film max outer diameter: ¢450mm;

Film volume core diameter: 75mm—78mm

3. Design speed (P / min): stable packing speed 100 packs/min

4. Overall dimensions(L*W*H): 6524×4055×1797(mm)

5. Power supply:3 Phase 380V 50HZ (The demand-er is responsible for providing the external power. Total power:15kw

| No. | Electrical Component | Power (kW) | No. | Electrical Component |

|---|---|---|---|---|

| 1 | Swing iron lift | 0.75 | 12 | Channel flap servo |

| 2 | Pull film servo | 0.4 | 13 | Down insert paper servo |

| 3 | Mid-send servo | 0.75 | 14 | Feed servo |

| 4 | Edge guide servo | 0.75 | 15 | Discharge motor |

| 5 | Cutter servo | 0.4 | 16 | Release film servo |

| 6 | Easy tearing servo | 0.4 | 17 | Tidy servo |

| 7 | Pressure package servo | 0.4 | 18 | Stacking motor |

| 8 | Sealing servo | 0.4 | 19 | Extended tail stock motor |

| 9 | Push rod servo | 0.75 | 20 | Total heating power |

| 10 | Support paper servo | 0.75 | 21 | Pad tissue motor |

| 11 | Forward servo | 0.75 | 22 | Other electrical components |

Machine net weight : 3000kg;

Compressed air (MPa):Pressure 0.5- -0.8 (the air source and external inlet pipe required b provided by the demander);

Noise:≤80dB;

Our spare parts manufacturing base:

4. Performance and Features:

- This Napkin Packing Machine has simple structure, with an easily adjustable and maintainable power and packaging system; Compact size, small footprint, easy to position and operate.

- The film cutters and dotted line cutters use a spring rotary cutter mode, operating only when material is present, so it improves the service life of the cutter.

- The packing machine has a turning-type pressing structure for easy adjustment, stable operation, and neat packaging.

- The intelligent interface automatically calculates packaging parameters once entered and saves them for quick replacements.

- The machine uses a three-dimensional packaging method with wrapping, folding, and edge sealing, ensuring a neat appearance and strong sealing effect.

- The anti-empty package function improves material sorting and tracking before feeding, preventing multiple bag feeding and incorrect paper length packaging. Unqualified paper towels do not pass through the packaging film, minimizing material waste.

- Electronic handwheel replaces the mechanical handwheel structure, providing industry-leading accurate control.

- It features an alarm protection function for detecting paper over-length and under-length errors, preventing packaging film waste and ensuring consistent product quality. This helps reduce the rejection rate of products..

- Optional Ribbon printer or heat transfer printer available.

- The conveying line can be customized in length according to the customer’s requirements or agreement.

- Equipped with automatic device to adjust and release film tension;

- The machine automatically stops the film if there’s no product, saving material.

- Open-close structure for the medium delivery channel with its own intellectual property rights.

- Optional special-shaped tearing parts available.

- Optional remote diagnosis module, visual inspection module and Internet of Things (IoT) available.

Packaging form and effect:

Electrical configuration list:

| NO. | Name | Brand | Remarks |

|---|---|---|---|

| 1 | Controller | KOSSI TECH | |

| 2 | Temperature controller | YU YAO | |

| 3 | Thermal protection | SCHNEIDER | |

| 4 | Servo motor | INOVANCE | |

| 5 | Servo driver | INOVANCE | |

| 6 | Push-button | INOVANCE | |

| 7 | Inverter | INOVANCE | |

| 8 | Photoelectric detection switch | BDL | |

| 9 | Relay | Omron、 SCHNEIDER | |

| 10 | Relay socket | Omron、 SCHNEIDER | |

| 11 | P-type general switch | JIU CHUAN | |

| 12 | Triple contact-or | SCHNEIDER | |

| 13 | Breaker | CHINT | |

| 14 | Proximity switch | BDL | |

| 15 | Solid state relay | CRYDOM | |

| 16 | Three-phase solid-state relay | CRYDOM | |

| 17 | HMI | MCGS | |

| 18 | Photo sensor | SICK | |

| 19 | Direct current stabilizer | MEAN WELL | |

| 20 | Direct head | AirTAC | |

| 21 | Solenoid directional valve | SMC | |

| 22 | Gear motor | HENGXING |

Special tools list:

| NO. | Name | Spec | Unit | Qty | Brand | Origin | Pr |

|---|---|---|---|---|---|---|---|

| 1 | ZB302H manual | pcs | 1 | China | SH | Fr | |

| 2 | Certificate | pcs | 1 | China | SH | Fr | |

| 3 | Guarantee card | pcs | 1 | China | SH | Fr | |

| 4 | Carton | pcs | 1 | China | SH | Fr | |

| 5 | Phillips screwdriver | pcs | 1 | China | SH | Fr | |

| 6 | Flat-head screwdriver | pcs | 1 | China | SH | Fr | |

| 7 | Monkey wrench | pcs | 1 | China | SH | Fr | |

| 8 | Allen key | Set | 1 | China | SH | Fr | |

| 9 | Air gun | pcs | 1 | China | SH | Fr |

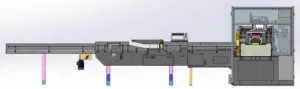

Full servo Napkin Packing Machine ZB302A

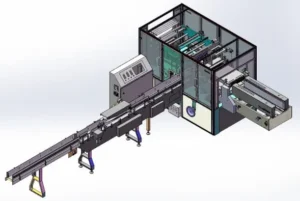

1. Appearance

2. Three views of the machine Figure 1 Dimensions of ZB302A

Figure 1 Dimensions of ZB302A

3. Features and Characteristics

- Full servo Paper Napkin Packing Machine start the host engine by 5 seconds to ensure the safety of personnel operation.

- The entire machine operation is controlled by the independently developed central control system, ensuring no abnormal vibration, overheating or noise;

- This napkin packing machine is designed neatly, with power supply and signal line connector securely enclosed.

- The machine tracks production status and faults automatically, with real-time alerts for easy operation.

- Include a 2m buffer storage belt.

- Flat packaging sealing with a smooth surface, no wrinkles or loose edges, ensuring a neat appearance.

- Membrane cutting and dotted cutting knives use a spring rotary design, powered by servo motor, which extends the knife’s service life when no material is present.

- The rolling film is powered by a servo motor and controlled by a controller, with an option to print patterns on the film.

- Has an automatic stop film function: no product, no film; no film used without a product.

- Made with stainless steel for parts that contact the paper, and a food-grade PU conveyor belt for safe handling.

- Uses a high-precision photoelectric eye tracking and monitoring system.

- The main motor speed is controlled by a frequency converter with a smooth operation function.

- Uses a central lubrication system.

- Has an intelligent temperature control system for easy and precise adjustment.

- Includes ultra-long and ultra-short product detection, along with torque limit overload protection to prevent damage to the main engine, paper feed, and edge guide.

16. Has three sets of variable frequency tally materials and five-section conveyor belt to enhance the machine’s production efficiency.

17. The feed is equipped with paper patting device to improve the product packaging quality.

18. Supports printing and production date on the packaging.

19. The conveyor line can be customized to the required length as per the customer’s specifications or mutual agreement.

4. Main technical parameters

- After replacement of individual parts, packaging specifications fit range L * W * H (mm): Length 120—400mm (Note: When the packaging length is 400mm, the maximum packaging Width 100—200mm Height 40—150mm

- Packing material: CPP (Double-sided heat sealing film); Film thickness: 0.04mm;

Film max outer diameter: ¢450mm;

Film volume core diameter: 75mm—78mm

- Design speed (P / min): 25- -80packs/min (subject to contract signing)

- Overall dimensions (L*W*H): 6310×4056×1696 (mm) (Excluding the date printing machine)

- Power supply: 3 Phase 380V 50HZ;Rated power:81KW (The customer is responsible for the power cord)

| NO. | Electrical Components | Power (kW) | NO. | Electrical Component |

|---|---|---|---|---|

| 1 | Main motor | 1.5 | 7 | Material motor |

| 2 | Pull film servo motor | 0.4 | 8 | Feed motor |

| 3 | Cutter servo motor | 0.4 | 9 | Extended tail frame motor |

| 4 | Medium feed servo motor | 0.75 | 10 | Tapping paper motor |

| 5 | Release film motor | 0.37 | 11 | Total heating power |

| 6 | Discharge motor | 0.37 | 12 | Other electrical components |

6. Machine net weight : 3500kg;

7. Compressed air (MPa):Pressure 5- -0.7 (the air source and external inlet pipe required are provided by the demand-er);

8. Noise:≤78dB;

5. Main electrical list:

| NO. | Name | Brand |

|---|---|---|

| 1 | Controller | Soontrue |

| 2 | Temperature controller | Ke Yang |

| 3 | Thermal protection | Siemens |

| 4 | Servo motor | Inovance |

| 5 | Servo driver | Inovance |

| 6 | Push-button | Schneider |

| 7 | Inverter | Inovance |

| 8 | Photoelectric detection switch | SICK |

| 9 | Relay | Omron |

| 10 | Relay socket | Omron |

| 11 | P-type general switch | Nine Sichuan |

| 12 | Triple contact-or | Schneider |

| 13 | Breaker | Chint |

| 14 | Proximity switch | Soontrue |

| 15 | Solid state relay | Crydom |

| 16 | Three-phase solid-state relay | Crydom |

| 17 | Encoder | Kuebler |

| 18 | HMI | MCGS |

| 19 | Photo sensor | SICK |

| 20 | Direct current stabilizer | MEAN WELL |

| 21 | Direct head | AirTAC |

| 22 | Solenoid directional valve | SMC |

| 23 | Gear motor | Hengying |

| 24 | Proximity switch | Soontrue |

6. Special tools list

| NO. | Name | Spec | Unit | Qty | Brand | Origin |

|---|---|---|---|---|---|---|

| 1 | ZB302A manual | pcs | 1 | Soontrue | SH | |

| 2 | Certificate | pcs | 1 | Soontrue | SH | |

| 3 | Guarantee card | pcs | 1 | Soontrue | SH | |

| 4 | Carton | pcs | 1 | Soontrue | SH | |

| 5 | Phillips screwdriver | pcs | 1 | Soontrue | SH | |

| 6 | Flat-head screwdriver | pcs | 1 | Soontrue | SH | |

| 7 | Monkey wrench | pcs | 1 | Soontrue | SH | |

| 8 | Allen key | Set | 1 | Soontrue | SH |

Packing effect

Remarks

1. The above quotation is based on FOB Shanghai trade terms.

2. Payment terms: 30% deposit before production and 70% balance before shipment.

3. Packing: Export standard packaging.

4. Delivery time: 30 working days upon receipt of down payment.

5. Warranty period: 12 months from the date of Bill of lading.

6. Quotation validity: The quotation is valid for one month, starting from November 14 to December 14, 2024.

Training & Installation

A. Once the equipment(s) and installation conditions are ready (including all necessary machines, materials, power, and air supply), we will send our technician(s) to buyer’ site for installation and staff training. We guarantee our staff(s) will comply with factory regulations and local laws.

B. The service charge is 100 US Dollar per technician per day. The buyer is responsible for covering visa arrangements, accommodation, food, transportation and insurance cost for our staff(s).

Guarantee

A. We guarantee that all our products sold and supplied are brand new, high quality and meets the performance and standard stated in the contract.

B. We offer a one-year warranty from the date of the Bill of Lading. During this period, we will be responsible for repairs, spare parts supply, and relevant service charges if the issue is due to product quality.

C. We guarantee that we will provide after-sales service and spare parts throughout the equipment’s lifespan.

D. We guarantee to respond to customer complaints or inquiries within 1 hours and spare parts requests within 48 hours. If on-site repairs or field assistance are needed, the issue will be resolved through mutual agreement.

FAQs on Napkin Packing Machine

What is Napkin Packing Machine?

A napkin packing machine is an automatic machine used to pack paper napkins into plastic or paper wrapping for hygiene and ease of distribution.

What types of napkins can this machine pack?

It can pack a variety of paper napkins, including standard, folded, and interleaved napkins, as long as the dimensions fit the machine’s packaging range.

Is the napkin packing machine suitable for different napkin sizes?

Yes, it can be set to fit different sizes of napkins and lengths of paper, to enable flexible operation.

What are the key features of the napkin packing machine?

– Simple structure with adjustable power and packaging

– Compact size for easy operation

– Spring rotary cutter for longer lifespan

– Intelligent interface for automatic settings

– Three-dimensional wrapping for strong, neat sealing

What type of packaging method does the machine use?

It uses a three-dimensional wrapping, folding, and edge-sealing method, ensuring a strong seal and neat package appearance.

Is this machine suitable for small businesses or only for large factories?

The machine is scalable. Small- to medium-sized manufacturers can use it efficiently, while high-capacity factories can run it for continuous large-scale production.

Does the machine require special film for packaging?

Yes, it works best with CPP double-sided heat-seal film, which ensures strong sealing and smooth packaging. Other heat-sealable films may be compatible if within thickness limits.

How fast can the machine pack napkins?

Production speed is up to approximately 100 packs per minute, depending on the napkin size and film type.

Can the machine be integrated into an existing production line?

Yes, it can be connected to conveyors, printers, or other pre- and post-processing equipment, making it flexible for factory automation.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province