Muffin Cup Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

4800W |

|---|---|

|

Voltage |

220V / 380V 50HZ |

|

Stroke |

|

|

Area |

2580(L)×1350(W)×1800(H) MM |

Product Description

About Muffin Cup Making Machine

The Muffin Cup Making Machine is a highly efficient machine that can produce muffin paper cups on an industrial scale. You can make maximum profit even with a small investment in this machine. It has reasonable pricing. It is a user-friendly machine that allows users to use this machine without prior knowledge of machinery experience.

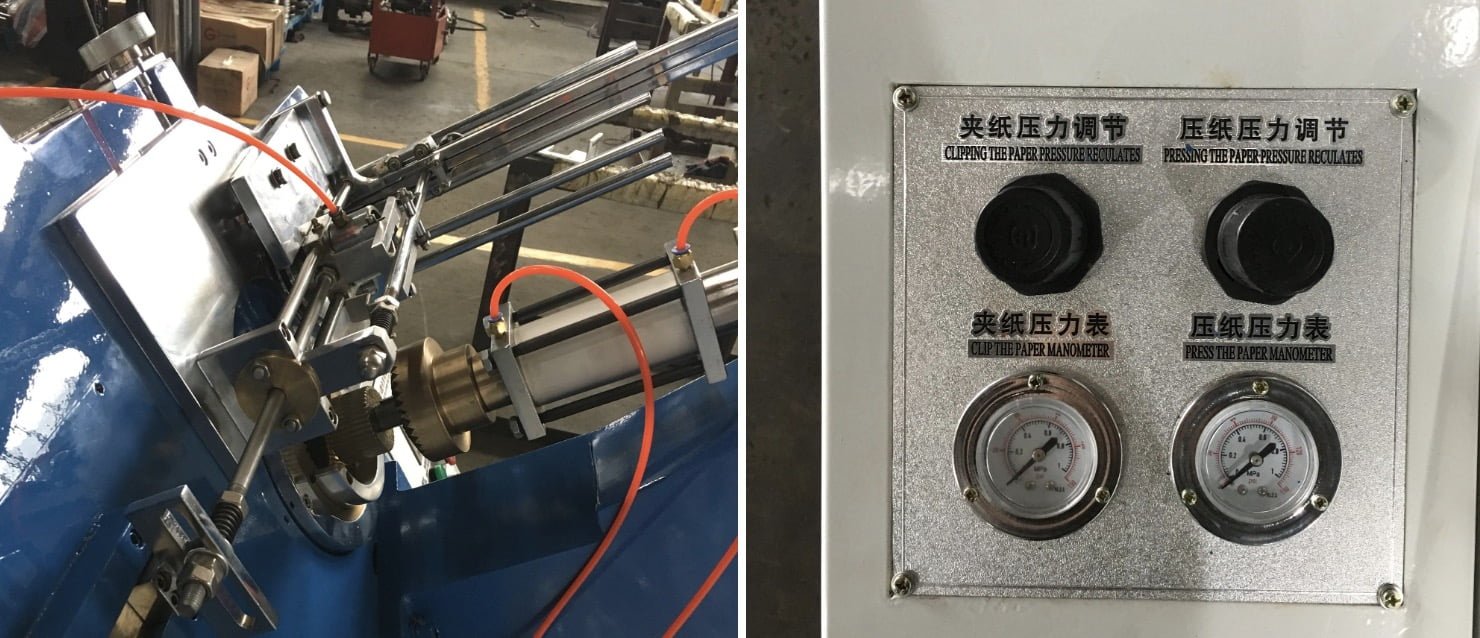

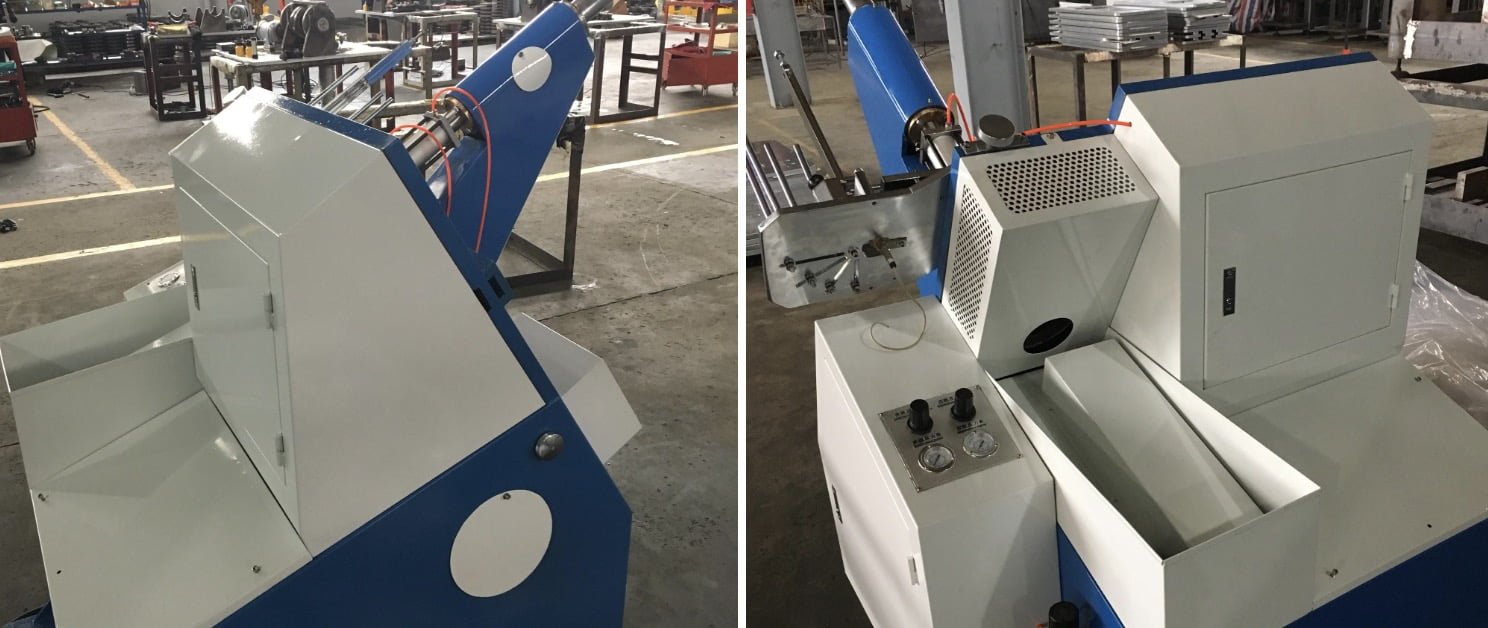

Product Appearance

MCCM-102 Muffin Cup Making Machine (general size)

Main Technical Parameters:

| S.N | Parameters | Description |

| 1 | Cup Size |

|

| 2 | Raw Material |

|

| 3 | Production Speed |

|

| 4 | Power Source |

|

| 5 | Total Power |

|

| 6 | Air Source |

|

| 7 | Weight |

|

| 8 | Packing Size |

|

MCCM-103 Muffin Cup Making Machine (extra size)

Main Technical Parameters:

| S.N | Parameters | Description |

| 1 | Cup Size |

|

| 2 | Raw Material |

|

| 3 | Production Speed |

|

| 4 | Power Source |

|

| 5 | Total Power |

|

| 6 | Air Source |

|

| 7 | Weight |

|

| 8 | Packing Size |

|

Machine Features and Advantages

| S.N | Features and Advantages | Description |

| 1 | User-friendly |

|

| 2 | Complete cup-forming |

|

| 3 | Eco-friendly |

|

| 4 | Simple, quality design |

|

| 5 | Customization |

|

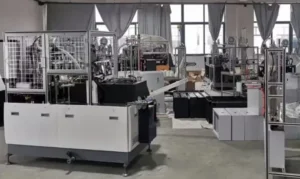

Product Display

FAQs

What is a Muffin Cup Making Machine?

The Muffin Cake Cup Making Machine is a highly efficient machine that can produce muffin cups on an industrial scale.

How many muffin cups can it produce in a minute?

Our muffin cup making machine can produce around 20-30 cups in a minute.

What is the raw material for the Muffin Cake Cup Machine?

The Muffin Cake Cup Machine uses kraft paper or oilproof paper as the primary raw material.

Are the MCCM-102 and MCCM-103 machines environmentally friendly?

Yes, both machines are designed to be eco-friendly and feature multiple running positions for efficient operation.

Are these machines cost-effective for small businesses?

Yes, they offer reasonable pricing, high efficiency, and low maintenance costs, making them a profitable investment even for small businesses.

Is the machine automatic?

Yes, these muffin cup-making machines are automatic with continuous and uninterrupted production speed.

Is cleaning these machines easy?

Yes, the paper-contact parts of the muffin-cup-making machine are easily accessible, making it simple for cleanup.

Is the output size of the muffin cup cake machine adjustable?

Yes, depending on the type of mold you use on the machine, the output size of the muffin cup cake container can be adjusted.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province