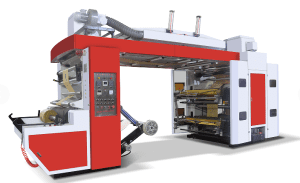

KGCI4-1600 4 Colour Flexo Printing Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

About KGCI4-1600 4 Colour Flexo Printing Machine

The KGCI4-1600 4 Colour Flexo Printing Machine operates as a high-performing precision printing solution that delivers high-speed and high-quality flexographic results. It prints paper materials between 15g and 500g. The machine implements advanced flexo printing technology which delivers accurate color reproduction together with steady print quality together with processing efficiency. Commercial businesses benefit from this 4 colour flexo printing machine which delivers reliable operation and affordable manufacturing alongside precision printing capabilities.

Appearance

Key Features of 4 Colour Flexographic Printing Machine

- Fast & High-Speed Printing: Maximum high-productivity printing speed of up to 200m/min.

- Precise Color Matching: With 4 ceramic anilox rollers (200 LPI) for enhanced ink transfer and color fidelity.

- User-Friendly Operation: The level of usability increases through touch screen controls and the print inspection system makes operation adjustments easy.

- Automatic Ink Circulation & Quick Wash System: Circulating ink systems and automatic washing abilities maintain operational cleanliness and prevent time losses.

- High-Quality Components: Uses Siemens PLC, Yaskawa Inverter, Schneider electrical components, and NSK bearings for durability.

- Energy-Efficient Drying System: The energy-efficient drying system incorporates dual heating together with central exhaust for quick ink drying functions alongside power consumption reduction.

- Heavy-Duty Construction: Built with a 75mm casting iron base (HT200) for stability and minimal vibrations.

Technical Specifications

| Specifications | Details |

|---|---|

| Model | KGCI4-1600 |

| Max. Material Width | 1600mm |

| Max. Printing Width | 1500mm |

| Material Compatibility | Paper (15g – 500g) |

| Printing Colors | 4 Colors |

| Printing Length | 400mm – 1000mm |

| Max. Printing Speed | 10 – 200m/min |

| Machine Speed | 220m/min |

| Printing Plate Thickness | 1.7mm Resin Plate |

| Adhesive Tape Thickness | 0.38mm |

| Machine Weight | 10T |

| Machine Dimensions | 7.5m (L) × 3.2m (W) × 3.5m (H) |

| Voltage | 380V, 3PHASE, 50HZ |

| Heating System | Electric heating, separate drying system |

| Control System | PLC (Siemens) + Touchscreen Interface |

| Drive System | Servo Motor |

Main Components

| Inverter | Yaskawa |

| PLC | Siemens |

| Touchscreen Interface | Weinview, Taiwan |

| Low voltage electric appliances | Schneider |

| Ceramic anilox roller | Yuncheng/Murata |

| Ink motor | Maily |

| Chamber doctor blade | China |

| Video Inspection | Pusai |

| Servo motor | Duochuan |

Remarks:

-

Terms of Payment: T/T Payment – 30% TT Deposit, and the remaining balance must be paid before shipping.

-

Loading Port: As specified in the quotation details.

-

Delivery Date: 50 days from order confirmation.

-

Packing: Film packaging in a container or customized packaging as per the buyer’s request.

-

Documents Provided: The seller will supply a commercial invoice, packing list, and Bill of Lading (B/L). If the buyer requires additional documents or certificates, the seller will provide them, but the buyer must cover all associated costs.

-

Origin: Made in China.

-

Order Policy: Once the deposit is paid, the order cannot be canceled or modified. The deposit is non-refundable.

-

Refund Policy: If the buyer requests a refund, the goods must be returned to the seller, and the buyer must cover the return shipping costs.

| Model | KGCI4-1600 |

| Deliver Time | 50 Days |

| Payment | 30% TT As Deposit for Order, 70% Before Shipment |

| Loading Port | FOB Ningbo Port of China USD |

| Optional

(Additional Cost ) |

|

| Guarantee | 1 Year |

| Spare Part | Included |

| Quotation Validity | 30 Days |

Printing Unit

- User components of printing include ceramic anilox roller together with chamber doctor blade and printing cylinder

- Central Drum Diameter: ¢800mm

- The available range of pressing roller girth extends from 400 to 1000mm with one free 500mm printing cylinder but extended sizes can be obtained through separate payments.

- Material of Plate: Resin plate 1.7mm

- The printing precision reaches ±0.1mm through use of a motorized system that controls horizontal and longitudinal registration.

- A self-operated system controls ink circulation together with a rapid washing system.

- Cylinder Mounting: Hydraulic system for fast plate changes

Traction Unit

- Traction Composition: Aluminum rollers and chrome-plated rollers

- Traction Zones: 2 zones

- Rear Traction Motor: Servo motor, 3.7kW

Unwinding & Rewinding System

The machine includes a pneumatic auto-loading unwinder to deliver seamless material delivery. Magnetic powder brakes (20kgs) provide automatic tension control for users. The surface roll rewinding system includes pneumatic auto unloading to enhance finished roll management.

- Max Unwind Diameter: 1200mm

- Max Rewind Diameter: 1200mm

- Unwind Type: Automatic tension control by means of pneumatic powered unwinding with self-adjusting tensions

- Rewind Shaft: Rewinding shaft comprises 1 air shaft with 76mm core diameter

Drying System

Electric heating with pre-blow drying serves to speed up drying time and prevents ink smudging through the system. The drying system contains independent air circulation components together with central exhaust vents which enable efficient temperature regulation.

- Power Consumption: 30kW

- Dryer Length: 3 meters

Electrical System

- Main Servo Motor: 7.5kW

- Ink Transfer Motor: 4 pcs which contain a built-in fan structure.

- Horizontal Registration Motor: 4 pcs

- Vertical Registration Motor: 4 pcs

- Printing cylinder entrance and exit motors: 8 pcs for rapid cylinder replacements.

Spare Parts for Free:

| Name | Qty. |

| Tool Box | 1 set |

| Screwdrivers (1-10#) | 1 pc |

| Oil gun | 1 pc |

| Hexagon spanner Set | 1 set |

| Switches & Buttons | 2 pcs |

| Contactor | 2 pcs |

| Heating Tube | 2 pcs |

| Relay | 4 pcs |

| Printing Cylinder Bearing | 4 pcs |

| Air Faucet | 5 pcs |

| Anilox Roll Gear | 2 pcs |

| Doctor Blade Sealing Tape | 5 pcs |

| Thermocouple | 2 pcs |

Why Choose the KGCI4-1600 4 Colour Flexo Printing Machine?

- Suitable for high-speed, high-quality paper products printing at up to 500g.

- Advanced technology and materials ensure superior performance.

- Tunable with accessories to improve efficiency and automation.

- Warranty and trustworthy after-sales service.

- One of the Best Flexo Printing Machine Suppliers in China.

Machine Pictures:

1. High-quality stable doctor blades for high-speed running

2. Delta brand computer and Siemens brand PLC

3. All high quality brands

4. Hydraulic automatic loading and friction winding

5. High quality EPC web guiding

6. Hydraulic lift cylinders automatically

7. Big center drum

FAQs on 4-Colour Flexographic Printing Machine

- What is the cost of the 4-colour flexo printing machine?

The cost of a 4-colour flexo printing machine is $7,999.00 – $40,000.00. - What types of materials can the KGCI4-1600 print on?

It prints paper, plastic film, and packaging substrate materials of 15 g to 500 g. - How long does it take to ship?

The machine can be shipped within 50 days after confirmation of deposit. - Can the machine be fitted with additional features?

Yes! Automatic viscosity control, shaftless unwinder, etc. are provided as optional options. - What type of support is provided after purchasing the machine?

We provide a 1-year warranty, spare parts, and reliable customer support. - What is a 4-colour flexo printing machine used for?

The KGCI4-1600 4-colour flexo printing machine is used to print designs on paper, film, and packaging materials.

- Is ink circulation automatic?

Yes, the 4-colour flexographic printing machine uses an automated ink circulation system. - Is printing speed adjustable?

Yes, the printing speed of the KGCI4-1600 flexo printing machine can be controlled as required by the operator. - Is it suitable for packaging printing?

Yes, the KGCI4-1600 flexo printing machine is widely used in packaging industries that require a large amount of prints over a period of time.

- Does it support multicolour printing?

Yes, as the name suggests, the KGCI4-1600 supports up to four colours.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province