Aluminium Foil Balloon Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

About Aluminium Foil Balloon Making Machine

Aluminium foil balloons are the centerpiece of every occasion. Whether it’s for a children’s birthday party or an adult celebration, the vibrant and unique designs of Aluminium foil balloons make a statement on every occasion. Replacing the traditional latex balloons, Aluminium foil balloons, or Mylar balloons has become a preferred choice worldwide. The aluminium foil balloon making machine is revolutionizing the balloon manufacturing industry.

Have you ever wondered how these balloons are made? In this blog, we discuss the Aluminium foil balloon making machine and the process of manufacturing Aluminium foil balloons.

Get your quote for the Aluminium foil balloon making machine, contact Kingsler Machinery today!

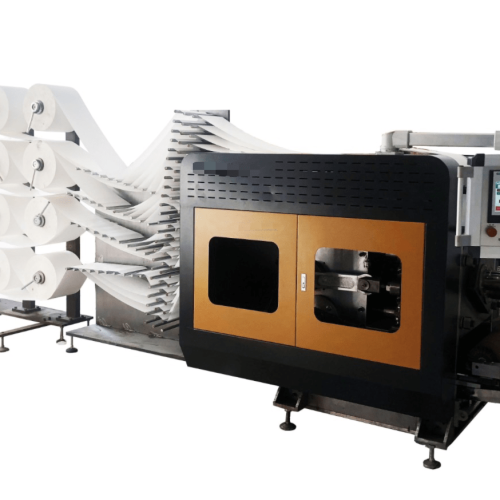

Appearance

How does the Aluminium Foil Balloon Making Machine work?

An Aluminium Foil balloon-making machine is used to manufacture Mylar Films or foil balloons, which are thin, shiny, and generally PET (polyethylene terephthalate). This machine uses a high-technology foil balloon-making machine using printed raw materials. This machine has replaced manual craftsmanship with automation and decreased human labor.

Here is a detailed process of the aluminium foil balloon manufacturing machine:

1. Material Feeding

The first stage of Aluminium balloon making is loading the film into the machine. First, put the printed aluminized film roll on the unloading equipment. The machine takes in the film smoothly and uses the rollers and tension controllers to prevent wrinkles or misalignment.

2. Film Alignment and Registration

The next step is Alignment and registration of the Film. After feeding the aluminium-coated PET film into the machine, the next critical step is alignment and registration. To create a foil balloon, the top and bottom layers of the film must be perfectly aligned before we cut and seal the final output.

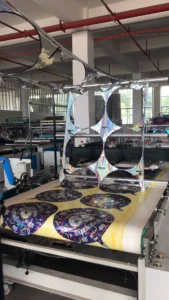

3. Cutting and shaping

After all, following all these steps, the foil is cut and shaped using the method called die-cutting. Die-cutting is a process of cutting using a die, a custom-shaped metal mold. Different shapes of balloons, such as stars, hearts, animals, and numbers, are cut out to the shape by pressing onto the film.

4. Inflation Port Sealing

The main edges of the balloon are sealed after it is cut. The next important step is sealing the inflation port. The inflation port is the small opening through which air or helium is pumped into the balloon. It allows the balloon to be inflated without over air pressure the balloon or bursting.

5. Output collection and packaging

Once the balloons are cut, sealed, and the inflation ports are in place, the final step is to collect, inspect, and package the finished foil balloons. This stage ensures that balloons are ready for the customers to inflate and enjoy.

Advantages of the Aluminium Foil Balloon Manufacturing Machine:

The foil balloon-making machine has replaced human labor as well as the latex balloon. The Foil Balloon comes in a unique variety, texture, and features. Here are the advantages of foil balloon-making machines:

- Custom foil balloon making process

- Easy and convenient process

- High-quality machine and result

- Support various sizes and shapes

Why choose Kingsler Machinery?

At Kingsler Machinery, we value innovation, engineering, and machines. We aim to provide custom and best products that increase value to our customers. With the proper speed, flexibility, and efficiency, Kingsler Machinery is the best choice for Foil Balloon manufacturing.

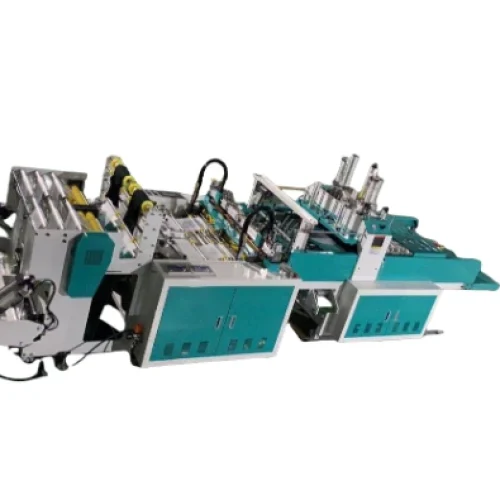

PRODUCT PIC:

The aluminium foil balloon is a crafty and unique balloon used for decorations on every occasion. With its shiny finish, it becomes the centerpiece of every event. The Aluminium Foil Balloon-making machine uses the finest technology to create custom foil balloons based on the customer’s desire. The balloons are made up of different colors, sizes, and varieties.

Contact Kingsler Machinery to get the best Aluminium foil balloon making machine in the market.

FAQs on Aluminium Foil Balloon making machine

How do you pump Aluminium foil balloons?

All aluminum foil balloons have a valve that allows air to be filled. In the aluminium foil balloons, Air is pumped using hand pumps.

What materials are in foil balloons?

The main material of a foil balloon is PET (polyethylene terephthalate).

How long do foil balloons last?

A foil balloon lasts for 3-5 days after its production.

Are foil balloons flammable?

Yes, foil balloons are flammable and are not resistant to fire. However, helium is not a flammable material, so it may not spread flames as intensely as you would think.

Are foil balloons plastic or metal?

Foil balloons are made up of nylon covers with a layer of aluminium.

Is the machine fully automatic?

Yes, the aluminium foil balloon-making machine is fully automatic, covering the forming of balloons and sealing as well as cutting for the required shape.

Is the machine easy to maintain?

Yes, the foil balloon making machine has a simplified transmission system and low maintenance needs.

What level of skill is required to operate it?

Anyone can operate the foil balloon-making machine with just basic operator training without much difficulty.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province