Automatic Non Woven Bag Making Machine – Fully Automatic & High Efficiency

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

About Automatic Non Woven Bag Making Machine

The OUNUO ONL-XA700 Fully Automatic Non Woven Bag Making Machine represents a state-of-the-art machine dedicated to serving the requirements of present-day eco-conscious packaging sectors. Users require this machine for rapid secure high-speed sustainable commercial manufacturing of shopping bags and flat bags along with box bags and vest-style bags.

This bag making machine delivers automated operations together with high-quality sealing and production versatility to manufacturers working in retail fashion food delivery and promotional packaging businesses.

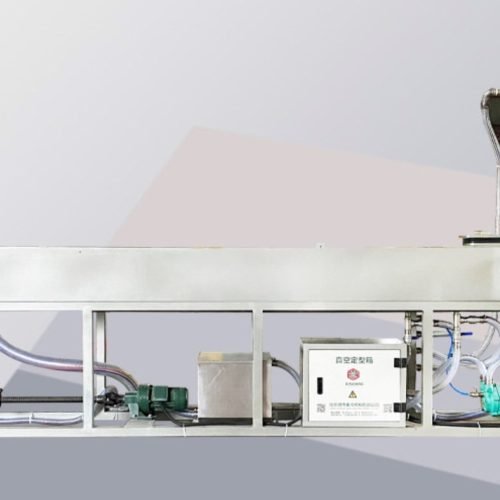

Appearance

Key Features of Fully Automatic Non Woven Bag Making Machine

Key Features of Fully Automatic Non Woven Bag Making Machine

- Full Automation

The automated machine conducts all manufacturing tasks by itself from raw material input to bag output including automatic feeding followed by sealing and cutting and punching and finish bag stacking to reduce employee work and mistakes.

- High-Speed Production

The machine design efficiency enables production speeds at 100 bags per minute which enables business expansion. - Ultrasonic Sealing Technology

The technology produces professional-level bags with neat edges as well as powerful seals. - Photoelectric Tracking System

The system provides precise bag shape alignment that guarantees perfect bag appearance for every piece. - Servo Motor Driven

Guarantees precise movement and consistency throughout the operation. - User-Friendly Touchscreen Interface

Real-time control simplicity allows users to track and modify machine parameters easily. - Tension Control System

The tension control system stabilizes material feeding to maintain continuous smooth production operations at all speeds. - CE and SGS Certified

The equipment meets international security standards together with quality standards. Your consumers will show enhanced faith in your product because of it.

Product Specifications

| Specification | |

|---|---|

| Brand Name | OUNUO |

| Model Number | ONL-XA700 |

| Machine Type | Fully Automatic Non Woven Bag Making Machine |

| Bag Type | Non-woven shopping bag |

| Capacity | 40–100 pcs/min |

| Total Power | 23KW |

| Operation Model | Computer touch screen |

| Color | White and Gray |

| Payment Terms | T/T, L/C |

| Delivery Time | 30 days |

| Supply Ability | 30 sets per month |

| Packaging Details | Shrink film and wooden case packing |

| Warranty | One Year |

| Certification | CE |

| Place of Origin | Zhejiang, China |

Bag Types Automatic Non Woven Bag Making Machine Can Produce:

-

Box bags

-

T-shirt bags

-

Flat bags

-

Shopping bags

-

Handle bags

-

File bags

-

Cloth bags

Supports non-woven fabric thickness ranging from 30 to 100 GSM, including laminated and recycled materials.

Main Technical Parameters

| Specification | Flat Bag | T-shirt Bag | Box Bag |

|---|---|---|---|

| Non-woven Bag Width (mm) | 100–700 mm | 300–600 mm | 300–600 mm |

| Non-woven Bag Length (mm) | 300–750 mm | 200–480 mm | 300–650 mm |

| Non-woven Bag Gusset (mm) | 40–90 mm | 40–120 mm | 40–80 mm |

| Bag-making Speed (pcs/min) | 20–90 pcs/min | 20–90 pcs/min | 20–90 pcs/min |

| Material Thickness (GSM) | 35–90 GSM | 35–90 GSM | 35–90 GSM |

Additional Machine Specs

-

Rewinding Material Diameter: 1000 mm

-

Rewinding Material Width: 1600 mm

-

Machine Weight: 4000 kg

-

Power Supply: 380V, 50Hz, Three Phase

-

Total Power: 16 KW

-

Machine Dimensions (L×W×H): 9200 × 2100 × 2000 mm (I Model)

-

Sealing System: 10 sets of top-quality ultrasonic units

Eco-Friendly Production

Non-woven material is recyclable, reusable, and biodegradable, making it an excellent choice for eco-friendly companies. As a leading automatic non woven bag making machine supplier, we offer solutions that allow a smooth transition to green packaging options—without compromising on quality or production efficiency.

- Feeding the Fabric

It begins by feeding rolls of non-woven material into the machine. Everything is automatic, so no manual handling is needed. - Shaping the Bag Mouth

The mouth of the bag is folded and sealed neatly to give it a clean edge. If handles are involved in the design, the machine is set up for that too. - Inserting the Handles (if required)

If the bag has rope or fabric handles, those get automatically threaded and placed straight on top. It is all done quickly and precisely. - Heat or Ultrasonic Bonding

The bag is closed using heat or ultrasonic bonding instead of a stitch. This tightens the bag and gives it a professional, clean look. - Folding the Sides

Sides of the bag are folded towards the inside in order to create a gusset. That is what offers the depth to the bag such that it will be able to hold more content in a suitable way. - Sealing the Bottom

The bottom is sealed shut after sealing the sides so that it is closed and can sustain weight without any issues. - Extra Bonding (if needed)

A number of bags need a second stage of bonding for additional support, especially those meant for heavy weight or box-like shapes. - Cutting to Size

The finished bag is then cut from the roll of material. This process is very precise so that every bag is the same size. - Counting & Stacking

Lastly, the bags are automatically counted and stacked on top of each other—ready for packaging or shipping.

Frequently Asked Questions

1: What is the production capacity of the Automatic Non Woven Bag Making Machine?

The production capacity of this automatic non woven bag making machine is 20–100 bags per minute, depending on the type of bag and material thickness.

2: What is the max unwinding and rewinding diameter?

This machine has a max diameter of 1000mm, suitable for mass production.

3: What kind of bags can I produce with this machine?

It can process different types of bags like flat bags, box bags, vest bags, and T-shirt bags.

4: What is the non woven bag automatic machine price?

The average price of an automatic non woven bag making machine typically ranges from $15,000 to $30,000 USD, depending on the machine’s configuration, production speed, automation level, and optional features

5: Does the machine require trained operators?

Not at all. The touch screen system of the computer makes the machine very simple to operate. A single operator can manage the entire process of production.

6: Is it energy efficient?

Yes, the machine is so designed as to consume minimum power while keeping productivity and quality high.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province