CTI-228 Fully Automatic Sheet Feeding Paper Bag Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

20000W |

|---|---|

|

Voltage |

|

|

Stroke |

50-70 times/min |

|

Area |

17200mm*1800mm+4500mm*1800mm |

Product Description

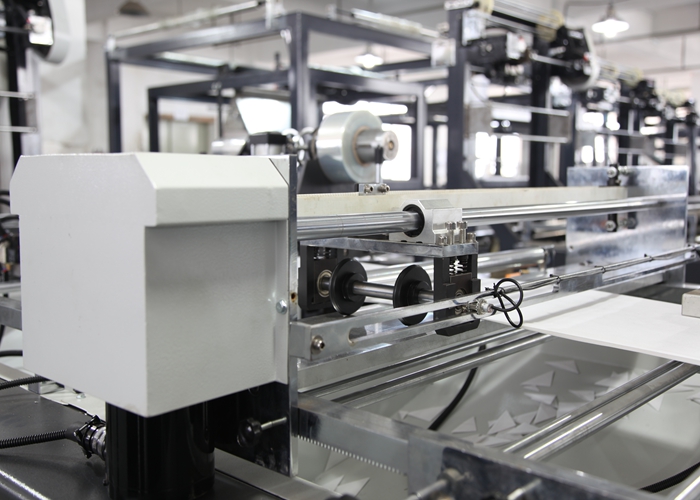

About CTI-228 Fully Automatic Sheet Feeding Paper Bag Making Machine

The CTI-228 Fully Automatic Sheet Feeding Paper Bag Making Machine is the ultimate solution for businesses seeking high-efficiency paper bag manufacturing. Supplied by Kingsler Machinery, a leading machine supply company in China, this machine is designed to meet different paper weights and different sizes of bags as it caters to businesses seeking eco-friendly accurate packaging solutions.

The machine reduces manual paper loading operations through its complete automation which simultaneously increases both output speed and manufacturing accuracy rates. Whether for retail, food packaging, or luxury bag manufacturing, the CTI-228 ensures seamless, high-quality bag production with minimal effort.

Appearance

Features of CTI-228 Fully Automatic Sheet Feeding Paper Bag Making Machine

- The machine operates at 50-70 bags per minute speed thereby boosting production throughput.

- The machine allows production of paper bags from 150mm to 450mm in width and 200mm to 550mm in height.

- The machine accepts paper materials ranging between 100g to 350g for various production needs.

- The machine implements advanced glue application technology which includes hot and cold glue functionalities for elevated bond strength.

- The machine provides precise folding operations between 25mm to 60mm which guarantees organized professional output.

- This operation mode reduces work requirements while maintaining consistent results.

How It Works

- The machinery operates a sheet feeding system which delivers paper contents into the system via precise mechanisms.

- The paper goes through folding and creasing operations which complete the gluing preparation.

- The gluing process utilizes hot and cold glue operated by the machine to enable solid adhesion.

- The manufacturing process includes forming the bags before the machine validates the bottom seam with added reinforcement for improved survivability.

- The production process ends with organized bag stacking that prepares them for delivery.

Product Specification

| DATA | |||

| Machine Size

L*W+W*H |

17200mm*1800mm+4500mm*1800mm | Weight | 14T |

| Min. Paper Sheet Size | 520mm*290mm | Power | 20kw |

| Max. Paper Sheet Size | 1160mm*590mm | Gusset | 55mm – 180mm |

| Bag Width | 150mm – 450mm | Paper Weight | 100g-350g |

| Bag Height | 550mm – 200mm | Speed | 50-70pcs/min |

| Glue | Cold & hot | Folding | 25mm – 60mm

|

High-Quality Components for Reliable Performance

Built with top-tier components, the CTI-228 ensures smooth operation and long-lasting durability.

| NO | Item Name | Brand | Origin | Model |

| 1 | Machine body | CTI | China | |

| 2 | Vacuum pump | ORION | Japan | CBX62-P-VB-03 |

| 3 | Paper feeding system | BSC | China | |

| 4 | Main motor | RUIYU | China | 13M-4 |

| 5 | Servo | Panasonic | Japan | |

| 6 | Air cylinder | AIRTAC | Taiwan | |

| 7 | Electric element | Siemens | Germany | RXM2LB2BD |

| 8 | Inverter | Panasonic | Japan | AVF200-0754 |

| 9 | Glue machine | KEKI | Joint venture | |

| 10 | Water glue machine | KEKI | joint venture | KPM-PJ-V2.4 |

| 11 | Main bearing | NSK | Japan | ZZ600 |

| 12 | Relay | SCHNEIDER | joint venture | DC24V、LRE14N |

| 13 | Contactor | SCHNEIDER | joint venture | |

| 14 | Air break switch | SCHNEIDER | joint venture | 3P/30A |

| 15 | PLC | Panasonic | Japan | |

| 16 | Feeding photo sensor | Panasonic | Japan | |

| 17 | Feeding system | BSC | China | |

| 18 | touch screen | MCSG | Joint venture | S-700 |

| 19 | Auto feeding component | WEIJIE | China | |

| 20 | Reducer motor |

Applications

CTI-228 Sheet Feeding Paper Bag Making Machine enables users to manufacture different kinds of paper bags at once.

- The CTI-228 machine manufactures retail bags which suit fashion stores alongside gift shops and boutique fashion brands.

- The food packaging bags that the CTI-228 produces serve bakeries and fast food outlets as well as grocery stores.

- The Luxury Shopping Bags feature the perfect packaging solution for high-end brands who demand premium products.

- These sustainable bags assist businesses to eliminate plastic products and achieve environmental sustainability goals.

Machine Details

Electrical Diagram

Benefits of Fully Automatic Sheet Feeding Paper Bag Making Machine

- The machine operates automatically to decrease operational expenses.

- Consistent Quality – Delivers uniform, high-quality paper bags with precise finishing.

- The CTI-228 machine enables sustainable manufacturing of eco-friendly bags for satisfying market requirements.

- Low Maintenance – Built with durable components for long-lasting performance.

- Users can easily operate this machine through touchscreen control while it utilizes automatic settings.

Paper Bags Samples

Frequently Asked Questions (FAQs)

1. What paper bag sizes can the CTI‑228 machine produce?

The machine can make paper bags with widths from 150 mm to 450 mm and heights from 200 mm to 550 mm, accommodating different bag formats.

2. What range of paper weights does this machine support?

It operates with paper sheets weighing 100 g to 350 g, allowing production of both lightweight and stronger bags.

3. How fast can this paper bag making machine produce bags?

It runs at a production speed of 50–70 bags per minute, which supports efficient, high‑volume output.

4. How much power does the CTI‑228 machine require?

This machine uses 20 kW of power during operation.

5. What types of paper bags can be made with this machine?

The CTI‑228 is suitable for retail bags, food packaging bags, and luxury shopping bags, providing eco‑friendly solutions for stores, restaurants, and branded packaging needs.

6. Does the machine use hot‑melt glue or cold glue?

It features both hot and cold glue application technology, which increases the adhesive strength of bag seams.

7. What size paper sheets are compatible with the CTI‑228 machine?

The machine accepts paper sheets from 520 mm × 290 mm up to 1160 mm × 590 mm, allowing flexibility for different bag sizes.

8. How durable and reliable is the machine?

Built with quality parts like Panasonic servo controls, Siemens electrical elements, and NSK bearings, the CTI‑228 supports reliable performance and long‑term durability with proper maintenance.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province