3SJ-GS1700ABC Blown Film Extrusion Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

The 3SJ-GS1700 Blown Film Extrusion Machine is a high-performance solution designed for producing top-quality three-layer co-extruded films, ideal for packaging and industrial applications. It supports raw materials like LDPE, LLDPE, MLLDPE, and EVA, featuring a robust total power of approximately 200kW.

| GENERAL SPECIFICATION | ||

| S.N | Components | Specification |

| 1. | Main machine: Blown Film Extrusion Machine |

|

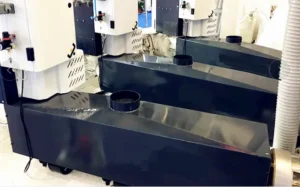

| 2. | Extruder

|

|

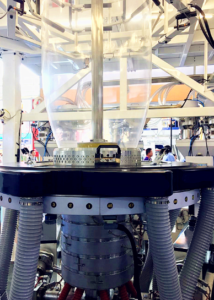

| 3. | DIE

|

|

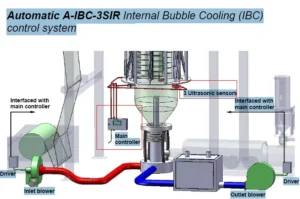

| 4. | Automatic A-IBC-3SIR Internal Bubble Cooling (IBC)

|

|

| 5 | Take-Up Unit

|

|

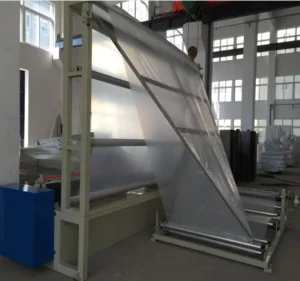

| 6. | REWINDING

|

|

| 7 | Switch Box

|

|

Explore our Large Capacity Plastic Recycling Shredders Plastic Crushing Machine

OPTIONAL EQUIPMENT FOR Blown Film Extrusion Machine

| 1. CAL-5HP-G4 Small centralized feeder CAL-5HP-G4

|

||

| S.N | Components | Specification |

| 1. | Control Method | PLC with digital control for precise automation |

| 2. | Conveying method | One-to-four conveying (for feeding by mixer) |

| 3. | Fan Power | Three-phase power 4.0kW |

| 4. | Specification | 3Φ, 400V, 50Hz electrical configuration |

| 5. | Conveying Capacity | Blown film extruder machine has the conveying capacity of 5m vertical height, 10m horizontal, not less than 300kg/hr |

| 6. | Diameter | 1.5″ duct diameter for material flow |

| 7. | Tube diameter | 1.5’’ for conveying tubes |

| 8. | Hopper volume | 12L*4 stainless steel vacuum hoppers; |

| 9. | Standard rubber hose | Stainless steel hopper with 12L, 4 units, or 12L + 4 stainless steel vacuum hoppers. |

| 10 | Remarks |

|

| 2. Weighing Dosing Machine CGB-200-4

|

||

| S.N | Component | Specification |

| 1. | Installation method | Installed on the Blown Film Extrusion Machine |

| 2. | Control Method | Siemens PLC controls with a Taiwan 7” color touch screen UI |

| 3. | Level Control | Germany IFM level switch |

| 4. | Valve Control | German FESTO solenoid valve for precise material flow regulation |

| 5. | Safety Switch | Equipped with SCHMERSRL safety switch |

| 6. | Cylinder Valve | Mingwei Taiwan cylinder valve for smooth mechanical operation |

| 7. | Sensor | American Celtron sensor for accurate weight or pressure detection |

| 8. | Contactor | Schneider France contactor |

| 9. | Relay | Japan Izumi relay for reliance signal control |

| 10. | Mixing Motor | Taiwan Taibang mixing motor |

| 11. | Materials | All parts in contact with the material are stainless steel for durability |

| 12. | Measurement Method | Weighing measurement (4 sets of main materials, standard pellets) for accurate dosing |

| 13 | Mixing capacity | >=200kg/hr |

| 14 | Power Specification | 1Φ, 230V, 50Hz single-phase power supply. |

| 15 | Application | Suitable for 3-5mm granular low-temperature plastic processing |

Unfolding Machine UZB1500-3000

| S.N | Components | Specifications |

| 1. | Max Rewinder width (mm) | 3000mm maximum width capacity |

| 2. | Max unwinder width (mm) | 1500mm maximum width capacity |

| 3. | Max rewinder speed (m/min) | 55 m/min maximum rewinding speed |

| 4. | Main motor power (kW) | 2.2 kW power with an inverter |

| 5. | EPC | Include |

| 6. | Tape inserter | Include |

| 7. | Unwinder and rewinder tension controller | Include |

| 8. | Tracking Photocell | 1 pc |

| 9. | Unwinder and rewinder roller | Air shafts for handling material rolls |

| 10 | Weight (kg) | 1000 kg capacity |

| 11. | Main Motor | Made in Shanghai |

| 12. | Inverter | KEWO brand |

| 13. | On and Off button | CHNT brand |

| 14. | Mini breaker | CHNT brand |

Contact us to get this machine at a reasonable price.

FAQs 3SJ-GS1700ABC Blown Film Extrusion Machine

What is a blown film extrusion machine?

A blown film extrusion machine is a machine that is used to produce films using different materials like LDPE, LLDPE, MLLDPE, and EVA.

What materials can be used in blown film extrusion?

Materials like LDPE, LLDPE, MLLDPE, and EVA can be used in blown film extrusion.

What is the main application of this machine?

The main application of this machine is to produce plastic film for various purposes like food packaging, agriculture, industry, construction, etc.

What are the key components of a blown film extruder machine?

Extruder, circular die, air ring, frame, roller, and winder are the key components of a blown film extruder machine.

Is the machine capable of producing multilayer films?

Yes, multilayer film production is possible depending on the machine model and setup.

Can film thickness be adjusted during production?

Yes, thickness can be controlled by adjusting machine settings during operation.

Is it suitable for bag production?

Yes, it is widely used to produce film for shopping bags, garbage bags, and food bags.

Does the machine support continuous operation?

Yes, it is designed for long and continuous production runs.

Is operator training required to run the machine?

Yes, basic training is needed to ensure safe operation and consistent film quality.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province

![Quotation of KN-700-3-zhongyuan (2)[1] – Protected View – Word 5_7_2025 6_05_29 PM wooden edge Banding Machine](https://kingslermachinery.com/wp-content/uploads/elementor/thumbs/Quotation-of-KN-700-3-zhongyuan-21-Protected-View-Word-5_7_2025-6_05_29-PM-r5gj8x6mlcns5job2eicr7vehl5z7tp71a6xb9ijk8.png)