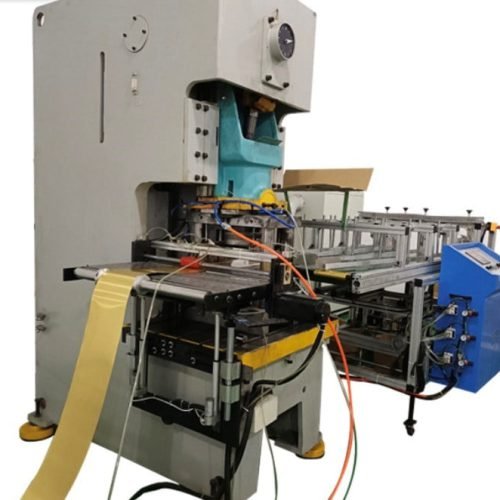

Full Automatic Table Cover Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

In today’s textile and packaging industries, being efficient, precise, and durable is critical to the success of any production line. The Mechanical Tablecloth Machine 500 is here to assist with reliable high performance, allowing customers to both produce and package tablecloths. The heavy duty construction, sophisticated control array, and general ease of operability, the Mechanical table cover making machine an excellent example of how good design can create efficiencies and ease of production.

Product Appearance:

Specifications for the Host

The dimensions of the table cover making machine are 2950 x 1800 x 1500 mm. This guarantees that the machine is large enough to accommodate broad raw materials and work areas, but small enough to fit in relatively small spaces of industrial workshops. The machine’s total weight is roughly 2 tons. This weight shows the machine is extremely well built. The heavy construction provides a good foundation that minimizes vibration when in operation and, therefore, variations in performance for long production runs.

Electricity and Voltage

The machine uses a 380V electrical supply (the electrical supply of choice for most industrial machines). The 380V design is suitable for supplying larger motors as well as the controls, and permits sustained operation of the machine under heavier loads and in extended production periods. The three phase electrical connection guarantees energy efficiency and a positive performance scenario.

Applicable Raw Material Size

One of the most important features of this machine table model is its variety of raw material sizes. It has the capability to handle raw material widths from 180 mm up to 350 mm. With this capability, it allows the manufacturer to produce any variation of tablecloth size, with minimal setup and change to the machine itself. The machine can easily satisfy the manufacturer’s needs for small decorative table covers or larger tablecloths, functional to the table setting.

Feeding System

The feeding system of the table cover making machine is designed for quick and easy loading of the material into the machine table. We have a manual feed system (gas inflatable). The gas inflatable shaft (1 shaft) securely clamps the raw material rolls while still being an easy and reliable loading technique. Although the feed system is manual, the gas inflate shaft fits the material with quick removal and insertion of the raw material roll, which saves installers a lot of setup time.

Control System

The table cover making machine utilizes an intelligent PLC + servo control system. PLC is a programmable automation technology, and servo motors make use of programmable computer technology for precise automated movement and accurate, smooth motions. Operators will use an uncomplicated human machine interface (HMI) to interact with the machine.

Material Taking Mode

Once the cutting process is complete, the machine automatically bags the finished tablecloth. However, the finished product still needs to be taken manually from the machine. This semi automated product taking system provides a balance between automation and manual labor. The machine has the ability to make finished products, but the operator’s attention is still needed regarding the final stage of the tablecloth.

Production Yield

The table cover making machine can produce a yield of approximately nine tablecloth products every minute. The output produced is conducive to medium to large size production levels of tablecloth manufacturing. This means over the course of a typical 8 hour shift, the machine will produce thousands of finished product tablecloth units. With the capacity of the machine, it is an efficient mechanism for businesses to utilize in order to eventually scale up production.

Parameter List of Mechanical Tablecloth Machine

| Item | Specification |

| Host Specification | 2950 x 1800 x 1500 mm |

| Weight | About 2 tons |

| Voltage | 380V |

| Raw Material width | 180 to 350 mm |

| Feeding Device | Manual feeding with an inflatable shaft |

| Control Device | PLC + servo control, simple human machine interface operation, automatic cutting of packaging bags, and conveying tablecloth into packaging bags to become a complete product |

| Material Taking Mode | After cutting, it is bagged automatically. Material is taken manually. |

| Yield | 9 pcs/ min |

Benefits of the Mechanical Tablecloth Machine

Sturdiness and Reliability: The table cover making machine weighs 2 tons and is engineered for an industrial environment.

Wide Width Variety: The machine table can accommodate raw material widths between 180 to 350mm and can produce tablecloths of nearly any size.

Automated Efficiency: With an automatic PLC+ servo driven system, the can cut, wrap, and wrap up to nine pieces per minute, perfect for the large quantity of output.

Reduced Operator Fatigue: The human machine interface enables even novice operators to be trained to operate this machine effectively.

Ideal Industry Applications

The table cover making machine is most suitable for staff in:

- Tableware and textile manufacturers

- Decorations for events suppliers

- Wholesale and retail tablecloth suppliers

- Manufacturers of packaging and household goods

With its combination of automation and manual inspection, the machine table is suitable for a range of business scenarios, from medium sized factories to full production plants.

FAQs on Table Cover Making Machine

1. What is the required power?

The machine has one that requires a power of 380V, which is a standard three-phase industrial supply.

2. What raw material widths can the machine support?

The machine supports raw material widths of 180 mm to 350 mm.

3. How does the material feed into the machine?

The feeding device uses a manual loading device with one (1) inflatable shaft to secure and hold material in place.

4. Is the process fully automated?

The machine provides the following process automation: cutting and bagging automation is available, but finished products have to be removed by hand.

5. What is the production capacity?

The machine has a production capacity of around 9 pieces per minute, making it appropriate for bulk production requirements.

6. What materials can this machine process?

This machine typically works with PE, LDPE, HDPE, and PVC plastic films commonly used in disposable table cover manufacturing.

7. How accurate is the cutting and sealing process?

The machine uses precision sensors and heat-sealing systems to ensure consistent size, clean edges, and strong seals.

8. What affects the price of a table cover-making machine?

Price depends on automation level, material width, output speed, control system, and optional features like servo motors.

9. Is this machine suitable for export-orientated manufacturing units?

Yes, it is widely used by export manufacturers due to stable performance, uniform output quality, and low labor requirements.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province