Automatic Foil Balloon Making Machine – Second Hand Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

The Model 700 Automatic Balloon Making Machine from Shantou Baofa Machinery Co. Ltd. is a sophisticated industrial machine that can manufacture aluminum foil balloons from PE, PP, and PET materials. Highly automated and intelligent, it provides high efficiency, quality control, and material use. It is ideal for the manufacturer of party supplies, decorations, and promotional items.

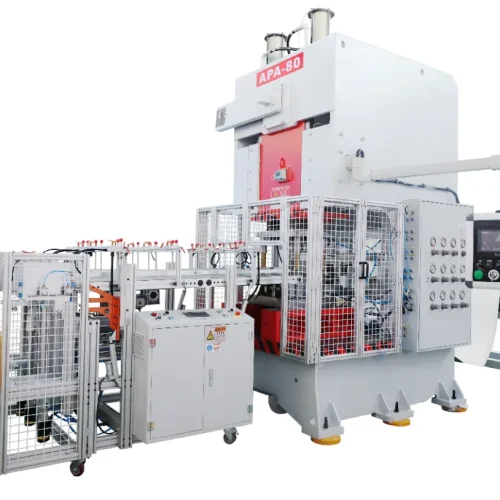

Product Appearance:

Equipment Summary

The Model 700 is a fully automatic aluminum foil balloon making machine that offers complete automation from foil feed to finished balloon. The next generation of automatic features provides:

User friendliness: This foil machines are user friendly and easy to use. It has a very quick parameter setup.

High production efficiency: It has a high production capacity of up to 15 to 45 balloons per minute.

Resource efficiency: It utilizes the materials efficiently and has less waste of raw materials. It also utilizes labor properly.

High quality seals: It has clean, tight, and dependable heat seals.

Automatic waste discharge: With the machine’s automatic waste discharge, it has increased the cleanliness and tidiness of the workplace.

Equipment Features:

- Control Cabinet

- Mechanical host

Features of the Automatic Foil Balloon Making Machine

Touchscreen HMI: It has a 7 inch colored touchscreen display for entering parameters.

Fault Self Diagnosis: System self diagnoses with alerts and screen display of faults. This feature helps to solve the machine fault easily.

High Sensitivity Photoelectric Tracking: This machine also allows for extreme accuracy in cutting and sealing.

Positioning Stop Function: It prevents the knife stick eliminating wasted foil.

Simplified Transmission System: Since this foil balloon making machine has a simplified Transmission system, it is highly dependable and also easy to maintain.

Main Technical Parameters

| S.N. | Specification | Detail |

| 1 | Dimensions(mm) | Main machine: 4600 × 1400 × 1200 |

| 2 | Air nozzle: 3300 × 1600 × 1900 | |

| 3 | Folding unit: 1500 × 1500 × 1900 | |

| 4 | Feeding unit: 2100 × 1600 × 2300 | |

| 5 | Weight | 3800 kg |

| 6 | Voltage | 380V |

| 7 | Max. Film WIdth | 700 mm |

| 8 | Production Output | 15 to 45 pisces per minute |

| 9 | Main Motor Power | 2.2 KW |

Installation Procedures

Now, let’s see some easy steps for the installation of the Foil Balloon making machine.

- In order for the equipment to be levelled, support the machine legs adjustably.

- When deciding on a location for the machine, consider operation, maintenance, and repair access.

Control Panel Functions

Heat Seal Up/Down 1 and 2: It controls the temperature of the sealing units.

Punch: Controls the punching switch for the balloon air nozzles.

Alarm: An audible warning alert for faults.

Start/Stop: Also controls the machine operation.

Heats 1 and 2: These are independent heating element switches.

Display screen: The control panel has a 7 inch touch display to control the complete system.

Operation Method

Preparation for the operation:

- Switch on the main power.

- Press the Run Preparation button.

- The servo motor will reset automatically for precision.

Automatic Cycle

The cycle of oil machines revolves from the first step of foil feeding. After foil feeding, the foil balloon making machine moves to the floating roller transfer. The 3rd step is cutting, followed by the conveyor, and the final product, of finished balloon, is extracted.

Manual Mode

Even though the machine is automatic, any step in the process of the foil balloon making machine can be operated manually.

Safety Precautions

Some safety precautions before running the foil machines are:

- Check that each device’s position and pressures of pressure heads are correct.

- Ensure that there are no foreign objects on the machine.

- Visually check the air pressure and cylinder reset.

Some safety precautions during running of foil balloon-making machine are:

- Do not place fingers around the indenter.

- Use emergency stop button only when required.

Some safety precautions after running foil machines:

- Disconnect the power supply.

Configuration List

Control System

- Yonghong, 7 inch color touch screen

- Hpmant frequency converter

- PLC and electrical controls built in-house

- Pneumatic cylinders fitted with damping rollers

Sealing & Cutting Section

- It has a 2.2 kW brake motor

- It has 3 × 2 kW Housine branded high power servo motors

- 3 imported Italian photoelectric color-mark trackers

- Feili brand lump-sum cutters

- It also consists of 6 heat controlled sealing devices

- Dual stepper motors for feeding foil from the nozzle

Feeding System

- 3-inch pneumatic shaft

- Manual loading system

- 2.5 kg magnetic powder brake

- 0.75 kW frequency regulated traction motor

Operational Manual Features

Work Page Functions: output speed, bag length, counter, modes (blank bag or color chase)

Work Modes: stop on count, alarm does not stop, delayed restart, feed before cut or cut before feed

Punching Settings: on/off, delay, punching time

Machine Parameters: Control, structure, prints, floating roller, servo speeds, air nozzle functions

Air Nozzle Settings: bag length, delay modes, electrostatics, fixed length, or print mode feeding

Security: password protections for settings

Abnormal Alarm Functions

- Main axle printing tracking error

- Upper axle printing error

- Lower axle printing error

- Air nozzle A print tracking abnormality

- Air nozzle B print tracking abnormality

Conclusion

The Model 700 foil machines are more than a machine. It is a complete balloon production system designed for manufacturers who are focused on improving their production productivity. With its precision automation, smart control, and solid design there is no other machine that can provide the same consistency in the production of balloons while also reducing your cost and downtime. The automatic foil balloon making machine is ideal for companies who want to dominate the market for decorative balloons at high volume and premium quality.

FAQs on Automatic Foil Balloon Making Machine

What types of foil balloons can this machine produce?

This machine is designed to produce aluminum foil balloons in various shapes and sizes using PE, PP, and PET laminated foil materials. It is suitable for standard party balloons, decorative balloons, and promotional foil balloons, depending on the mold and cutting configuration used.

Is a second-hand foil balloon making machine reliable for production?

Yes, a second-hand machine can be reliable if it has been properly inspected, tested, and maintained. This model is built with industrial-grade components, automatic fault detection, and stable sealing systems, which makes it suitable for continued commercial use when serviced correctly.

Does the machine support different balloon sizes and designs?

Yes. The machine supports adjustable balloon sizes within its maximum material width capacity (up to around 700 mm). Different balloon shapes and designs can be produced by changing molds and adjusting cutting and sealing parameters.

What is the production speed of an automatic foil balloon making machine?

According to the machine specifications, production speed typically ranges between 15 to 45 balloons per minute, depending on balloon size, shape complexity, and material thickness.

How much power does this foil balloon making machine consume?

The machine operates on industrial electrical power and requires a stable voltage supply as specified in the technical data. Power consumption is optimized through automated operation and precise temperature control, helping reduce unnecessary energy waste during production.

Is special technical skill required to operate this machine?

Basic operator training is sufficient. The machine uses a touchscreen control system with automated settings and fault alerts, making daily operation straightforward. However, initial setup, mold changes, and maintenance should be handled by trained technicians.

What maintenance is required for this machine?

Routine maintenance includes cleaning sealing components, checking cutting blades, monitoring temperature systems, and inspecting electrical connections.

Who is this machine best suited for?

This machine is ideal for balloon manufacturers, party supply factories, and businesses looking to expand foil balloon production with a lower investment by choosing a second-hand automatic system instead of a brand-new machine.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province