APPM-0001 Automatic Plate Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

9000W |

|---|---|

|

Voltage |

380V 50Hz |

|

Stroke |

|

|

Area |

3000Lx1700Wx1700H (mm) |

Product Description

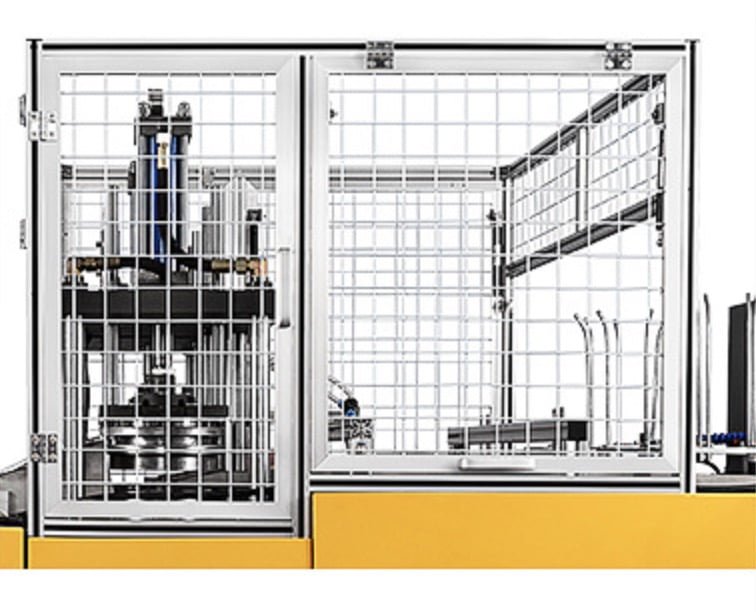

APPM-0001 Automatic Variety Plate Machine

Main Technical Parameters:

| Paper Size | 4-12 Inch |

| Production Speed | 100-140 pcs/min |

| Air Pressure | 0.3 m3/min |

| Row material | 140-1000g/m2 original paper or PE-coated paper |

| Power Voltage | 380V 50Hz |

| Total Power | 9.0KW |

| Weight | 2000Kg |

| Package size | 3000L×1700W×1700H (mm) |

Machine Features and Advantages:

- Simple operation, easy maintenance, and high safety operation.

- Equipped with an automatic collection device which means high efficiency and stable performance.

- New product- developed and researched to meet the market and customer requirements.

- Can make various shapes of plates: round, rectangle, square, circular, or irregular.

- Can make paper plates or aluminum foil laminated paper plates.

- Support customization – can make all kinds/sizes of the paper plate with the change of mold.

A. PLC Control System

Brand accessories: Using Delta, Schneider, and other high-quality brands electrical system control systems using Delta brand, reliable quality.

B. Smart touchscreen

Easy and convenient operation: touch screen and PLC interaction, all the working parameters can be set on the control panel for parameter setting and adjusting.

C. Sensor- fault self-check

Sensor failure automatic detection, failure will automatically stop working, greatly improving safety, error information will be displayed on the PLC touch screen.

D. Electrohydraulic system

Pressure up to 5T: Hydraulic oil circulation, less air required, energy saving, stable molding plate, To meet the requirements of sheet metal forming of different thicknesses. Adopt a fan cooling system to cool down and prolong service life.

E. Statistical collection

System design: The counting collection system with a sorting function can stack the finished paper trays in order, which is convenient for packaging and saves labor costs.

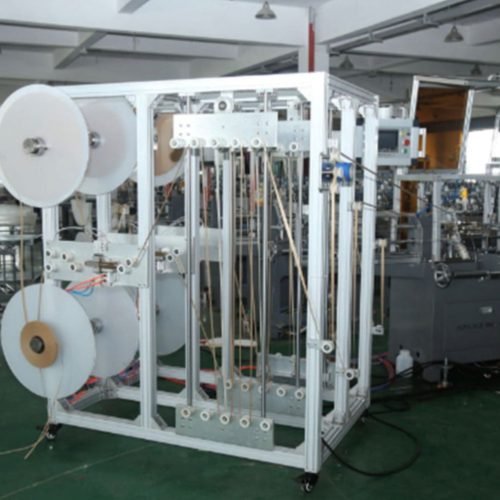

1. Conveyer System – the finished product is transported on a conveyor belt for easy collection.

2. Plate forming mold – mold quality is durable, longer service life, mold design can be customized as per customer needs.

3. Safety protective cover – protection during machine operation, higher safety, and reduces chances of incidents.

4. Design of multi-layer suction cup – Use multi-layer suction cups for better results, good quality, and longer service life.

Product Display

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province