Aluminium Foil Container Making Machine H-TYPE

|

Payment Terms |

L/C, T/T at sight |

Power |

11KWW |

|---|---|

|

Voltage |

220 |

|

Stroke |

20-45 times/min |

|

Area |

1220*1500*1200 |

Product Description

About Aluminium Foil Container Making Machine

With the improvement of people’s quality of life and the enhancement of environmental protection awareness, aluminium foil containers have become an irreplaceable daily necessity in people’s daily life.

Kingsler Machinery is an excellent enterprise specializing in the research, development, manufacturing and sales of aluminium foil container making machine’s production equipment. We are committed to the development, design and manufacture of aluminum foil lunch boxes and other aluminum foil products production lines and molds.

After years of efforts, our products have been radiated to all provinces and cities in China and exported to the Middle East, Africa, Europe, North America, South America, Southeast Asia and many regions in the world.

With dedication to customer services, Kingsler Machinery follows the business principle of “Quality as the guarantee, Research and Marketing as the soul, Management as the foundation”. With a strong team of senior engineers, technicians, and management staff, we ensure first–class product quality and excellent service.

In addition, we have established long-term strategic partnerships with trustworthy suppliers of raw materials, spare parts, and technical support. This ability to tailor solutions based on customer specifications, along with rigorous production processes, has earned us a good reputation in the market.

As a dynamic and forward-looking company, Kingsler Machinery remains dedicated to providing high-quality products and outstanding services to new and established customers.

RZLH Series

RZLH series is designed to be effective and precise in operations, with as its basic mechanism an advanced high-speed pneumatic punching machine of new technology. It boasts a precision automatic oiler feeder in combination with simultaneous material feeding and both semi-auto and auto-product pickup stackers (with either single-track or multi-track options). This machine effectively boosts efficiency in production but reduces the operating costs.

Key Features

1. Flexible Mold Options – Both single-cavity and multi-cavity molds are supported, allowing for higher productivity.

2. Advanced Control System – Equipped with an efficient quality electrical and control system for better precision, stability, and safety.

3. Tailor-made Solutions – The production line may be tailored with different configurations and electrical parts to serve specific customer requirements.

QUOTATION

| Validity:30 days | |

| MODEL AND DESCRIPTION | UNIT PRICE (EXW) |

|---|---|

| ALUMINUM FOIL CONTAINER MACHNE |

| PAYMENT TERM | After signing the contract, a 30% advance payment of the total amount is required. The remaining balance must be paid before delivery, following successful machine testing and factory acceptance. |

| Delivery time | The estimated delivery time is approximately 90 working days after receiving the deposit. The final delivery date will be confirmed by the factory based on order details and production schedules. |

| Electrical equipment | This machine adopts three-phase 380v. If you have any special requirements, please explain in advance with my company. |

| Guarantee | We provide a 12-month warranty with free replacement of parts damaged due to quality issues. However, damages caused by improper use (including unauthorized modifications to the PC or touch screen software) are not covered, except for standard wear-and-tear parts. |

| INSTALLATION | Our engineers are available for on-site installation and debugging, both domestically and overseas. For overseas service, the buyer covers all costs, including visa fees, airfare, accommodation, meals, and a daily salary of $100 per person. |

I. H-TYPE PRESSES MACHINE

1. PRODUCT FEATURES

The RZLH series presses represent a new generation of closed-type presses, developed with advanced foreign technology to meet customer needs. Engineers weld the machine’s body using a gantry-integral steel plate, eliminating the assembly and debugging required in traditional split-body presses. This design unifies the accuracy, rigidity, and strength of closed-type presses with simplicity in installation and operation of open-type presses. The prominent features are:

– Steel Plate Gantry Structure: Welded structure made of high-strength steel offers outstanding rigidity and long-term stability. The overall structure is annealed to ensure improved accuracy retention.

– Crankshaft Design: Placed longitudinally with short pivot distance, which offers high crankshaft stiffness.

– Enclosed Transmission: Gear components are immersed in oil to offer best lubrication and protection.

– Safety Features: Equipped with two-degree drop protection device and hydraulic overload protector. Overload protector holds the slider in place and triggers an electrical signal to prevent equipment and mold damage.

– Heavy-Duty Clutch and Brake: Strong interlocking dry pneumatic friction clutch-brake system with high torque and low rotational inertia, easy to install, and low maintenance.

– Accurate Slider: High-pressure oil seals welded steel plate construction to guarantee no leakage.

– Advanced Guiding System: Eight-edged high-precision guide rails offer higher guiding precision and long-time precision retention.

– Pneumatic Balancing Device: Reduces secondary shock for smoother running and improved dynamic accuracy.

– Safety Valve: American ROSS safety duplex valve ensures safe clutch operation, prioritizing operator safety operation, prioritizing operator safety.

Additional Features:

– Thin Oil Lubrication: Equipped with progressive distributor and lubrication fault detection switch.

– Balancing Cylinder Lubrication: Taiwan Yuxiang manual thin oil lubrication extends the service life of the balancing cylinder.

– Pneumatic Components: Employs Taiwan ADATA and Japan SMC components in air source treatment, regulators, and other devices.

– Lighting and Blowing Components: Equipped with a single lighting within the die area and an entire set of blowing components for clearing the material.

– Product Counting System: Equipped with a 4-digit count display buzzer to set up and track counts of products that can be activated or deactivated.

– Mitsubishi PLC and Touchscreen: Features front and rear photoelectricity, Mitsubishi PLC touchscreen for convenient operation, and 803 electronic cam.

– Solenoid Valves: With 12 SMC 24V solenoid valves (10020739), all pertaining to an electronic cam for accurate control.

– Work Lights: Placed on left and right windows, with a clear view when working.

– Machine Color: Finished in the same standard machine JF21-80 color.

– Electrical Junction and Gas Circuit: The left has the electrical junction box mounted and the right has gas circuitry components.

– Vibration Damping: Includes vibration damping pads (S78-10-07) to facilitate working.

– Electric Control: No electric control cabinet; yet, provision of retaining the button station and electrical interface is kept for flexibility.

– Storage Tanks: Six small storage tanks for gas are kept below the machine table with drain valve, air outlet, air inlet, and safety valve for good air management.

– Two-Hand and Foot Switches: The machine is supplied with two-hand operation buttons and foot switches for continuous, single, or inching operation.

This press is better in shearing, punching, falling, bending, and shallow stretching operations, offering high accuracy, strength, and reliability for various industrial applications.

2. MAIN TECHNICAL PARAMETERS

| NAME | UNIT | RZLH-63A | RZLH-80A | |

| NOMINAL FORCE | KN | 630 | 800 | |

| NOMINAL FORCE STROKE | mm | 4 | 5 | |

| SLIDER STROKE | mm | 260 | 280 | |

| TRIP TIMES | INVERTER | TIMES/MIN | 20-45 | 20-40 |

| MAX. LOADING HEIGHT | mm | 800 | 850 | |

| MAX. ADJUSTMENT HEIGHT | mm | 80 | 80 | |

| PLATE DIMENSION (FRONT AND BACK × LEFT AND RIGHT × THICKNESS) | mm | 1300×1400×95 | 1300×1700×95 | |

| BILE TABLE SIZE (FRONT/BACK × LEFT/RIGHT × THICKNESS × NUMBER OF PIECES) | mm | 1300×250×300×2PCS | 1300×250×300×2PCS | |

| SLIDER BOTTOM DIMENSION (FRONT TO BACK × LEFT TO RIGHT) | mm | 520×1020 | 520×1130 | |

| UPPER TEMPLATE SIZE (FRONT TO BACK × LEFT TO RIGHT) | mm | 500×600×95 | 500×600×95 | |

| MACHINE BODY WORK AND GROUND DISTANCE (EXCLUDING SHOCK PAD HEIGHT) | mm | 520 | 520 | |

| COLUMNS DISTANCE | mm | 1400 | 1700 | |

| MOTER POWER | kW | 11 | 18.5 | |

| AIR PRESSURE | MPa | 0.55 | 0.55 | |

| TOTAL WEIGHT | Kg | 11350 | 13950 | |

Note: The manufacturer reserves the right to replace the same brand

3. MAIN CONFIGURATION

| NO. | NAME | BRAND/ORIGIN |

| 1 | STEEL PLATE WELDED BODY, FIREPLACE ANNEALED | RUIZHI |

| 2 | DRY TYPE CLUTCH | HIGH PERFORMANCE, HIGH TORQUE CLUTCH |

| 3 | BEARINGS | TILE SHAFT |

| 4 | SIMMERRING OIL SEAL | NAK |

| 5 | SAFETY DUPLEX VALVE | ROSS |

| 6 | HYDRAULIC OVERLOAD PROTECTION | SHOWA JAPAN |

| 7 | HYDRAULIC OVERLOAD HIGH PRESSURE OIL SEAL | DICHTOMATIK |

| 8 | MODULATION MOTOR | Beijing Fute Disc Brake Motor Or products from Hunan Yuejin Motor Co., Ltd |

| 9 | ELECTRIC GREASE MAIN LUBRICATION SYSTEM | CNP |

| 10 | MANUAL LUBRICATION PUMP FOR BALANCE CYLINDER | ISHAN (ZHEJIANG OR TAIWAN) |

| 11 | AIR SOURCE TREATMENT TWO-PIECE, REGULATOR | SMC |

| 12 | MAIN MOTOR | SIEMENS |

| 13 | BUTTONS | SCHNEIDER |

| 14 | MOLD LIGHTING | OUDEN |

| 15 | SECOND-DEGREE DROP DETECTION SWITCH | SCHNEIDER |

| 16 | BOLTS, SCREWS AND OTHER FASTENERS | JINGYI TAIWAN |

| 17 | BLOWING PIECES (BLOWING) DEVICE ONE GROUP | AIRTAC TAIWAN |

| 18 | COPPER RAIL | SPECIFIC ALLOY STEEL |

4. IMPLEMENTATION AND STANDARDS ACHIEVED

| QC/YL 10-2012 | Gantry press (enterprise internal control standard) |

| GB 26483-2011 | Mechanical presses Noise limits |

| GB 17120-2012 | Forging and pressing machinery Safety and technical conditions |

| GB 5226.1-2008 | Electrical safety of machinery Electrical equipment of machinery Part 1: General technical conditions |

5. CONDITIONS OF USE AND ADAPTED ENVIRONMENT

| TEMPERATURE | -10℃—40℃ |

| RELATIVE HUMIDITY | ≤90%RH |

| VOLTAGE | 380V/50Hz±10% |

| CONTROL VOLTAGE | 220V/50Hz±10% |

| PNEUMATIC PRESSURE | ≥0.55Mpa |

| PROCESSING MATERIAL | COLD-ROLLED OR HOT-ROLLED STEEL SHEET |

II. FEEDER

1. PRODUCT FEATURES

- The machine adopts a split tension-free feeding mechanism on the basis of high-tech wrinkle-free product technology. The feeding headstock is installed directly on the punching machine for convenient installation, time-saving, and easy handling.

- The feeder has a safety chuck for convenient, efficient, and safe operation. The feeder gives a choice of 3-inch or 6-inch gas expansion shafts to allow rolls easy loading and materials feeding quickly. Zero tension-free tracking feed gives smooth operation, rapid left-right alignment adjustment, and easy oil lubrication.

- The feeder utilizes foreign rubber material and a three-axis oiling system to deliver even and stable lubrication without wrinkles of material. The running is oil-conserving and clean, and the life of the rubber shaft is extended.

- The feeding head frame uses double servo synchronous feeding with a planetary reducer, ensuring high precision, stability, and compatibility with both wrinkled and wrinkle-free products. It features a user-friendly interface with language conversion, product counting, and memory functions for enhanced flexibility and operation.

- The double servo synchronous feeding by planetary reducer is used within the feeding head frame for precision, stability, and compatibility with wrinkled and wrinkle-free products. The user-friendly interface consists of language conversion, product counting, and memory functions for increased flexibility and operation.

- Non-stop feeding without halting the punching machine, tracing color code of materials.

2. MAIN TECHNICAL PARAMETERS

| TECHNICAL PARAMETERS | RZ-800 | RZ-900 | RZ-1000 | RZ-1200 | RZ-1300 |

|---|---|---|---|---|---|

| FEED WIDTH (mm) | 800 | 900 | 1000 | 1200 | 1300 |

| FEED THICKNESS (mm) | 0.04-0.15 | 0.04-0.15 | 0.04-0.15 | 0.04-0.15 | 0.04-0.15 |

| FEED SPEED (M/min) | 20 | 20 | 20 | 20 | 20 |

| FEED ACCURACY (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| POWER (Kw) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 |

| VOLTAGE (V) | 220 | 220 | 220 | 220 | 220 |

| BODY DIMENSION (mm) (L*W*H) | 1220*1500*1200 | 1220*1600*1200 | 1220*1700*1200 | 1500*1930*1300 | 1500*2030*1300 |

| HEAD DIMENSION (mm) (L*W*H) | 600*950*1070 | 600*1050*1070 | 600*1150*1070 | 600*1400*1070 | 600*1500*1070 |

| TOTAL WEIGHT (kg) | 530 | 630 | 730 | 930 | 1030 |

Note: The manufacturer reserves the right to replace the same brand

Example: According to the size of the front and rear table of the H-type press, the width of the feeding machine can be matched, the feeding size can be ≥ the size of the front and rear table

63T with feeding width 1300mm

80T with feeding width 1300mm

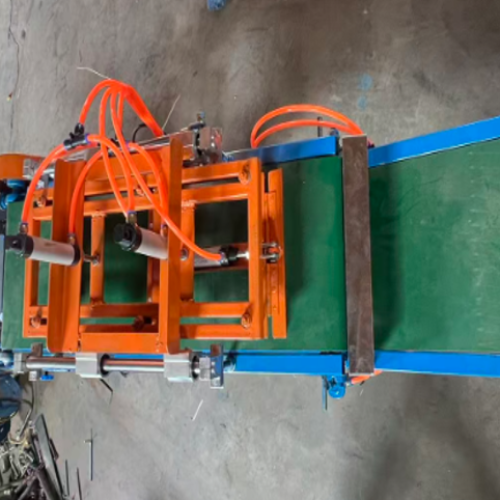

III. STACKER

1. PRODUCT FEATURES

- Adopting a profile frame structure, this machine features a solid and attractive appearance, designed to accommodate various aluminum foil meal boxes, containers, and packing boxes.

- The adjustment for all types of aluminum foil containers can be done tool-free, ensuring simple and convenient operation.

- It is suitable for various aluminum foil container molds and is equipped with a mold jamming and discharging detection function, which has better protection for the molds and machinery.

- The lifting platform uses a self-designed servo lifting structure that has high accuracy, fatigue resistance, and long lifespan.

2. MAIN TECHNICAL PARAMETERS

| TECHNICAL PARAMETERS | RZ-1 | RZ-2 | RZ-3 | RZ-4 | RZ-5 |

|---|---|---|---|---|---|

| LINES | 1 LINE | 2 LINES | 3 LINES | 4 LINES | 5 LINES |

| THICKNESS (mm) | 0.04-0.15 | ||||

| SPEED (M/min) | 20 | ||||

| POWER (Kw) | 0.75 | 1.5 | |||

| VOLTAGE (V) | 220 | ||||

| BODY DIMENSION (mm) (L*W*H) | 2610x810x1550 | 2610x1130x1550 | 2610x1430x1550 | 2610x1622x1550 | 2610x1870x1550 |

| TOTAL WEIGHT (kg) | 300 | 400 | 500 | 700 | 800 |

3. BASIC CONFIGURATION

| NAME | NO./ SERIAL NUMBER | BRAND |

|---|---|---|

| Stacking machine cylinder | SC40x400S | SMC |

| Touch Screen | SMART 700IEV3 | Mitsubishi |

| PLC | FX3GA-60MR | Mitsubishi |

| Frequency converter | FR-D740-1 | Mitsubishi |

| AC Contactors | LC1N0901 | Schneider |

| Relays | RXM24VDC | Schneider |

| Signal Amplifier | FX-101-CC2/UFX101CC2 | Matsushita |

| Fiber optic | PRC4Y20TZ10X/PTC4Y20TZ16X | – |

Note: The manufacturer reserves the right to replace the same brand

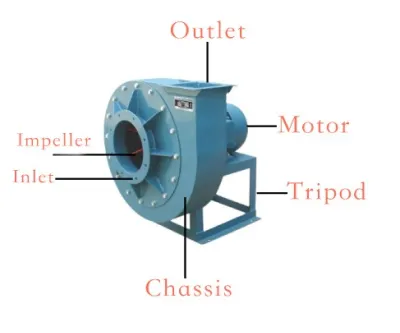

IV. Fans

FAN MAIN FECHNICAL PARAMETERS

| Model (N2) | Drive type | Power (KW) | Rotation (r/min) | Volume (m3/h) | Pressure (Pa) | Diameter of air inlet | Diameter of air outlet | Total weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 4A | A TYPE | 3 | 2900 | 1226-2339 | 2822-2577 | Φ175 | Φ150 (160) | 83 |

| 4.2A | A TYPE | 4 | 2900 | 1419-2708 | 3110-2841 | Φ200 | Φ150 (175) | 98 |

| 4.5A | A TYPE | 5.5 | 2900 | 1745-3330 | 3571-3262 | Φ200 | Φ175 | 113 |

| 4.75A | A TYPE | 7.5 | 2900 | 2052-3917 | 3979-3634 | Φ225 | Φ200 | 128 |

Note: Type A is motor direct connection

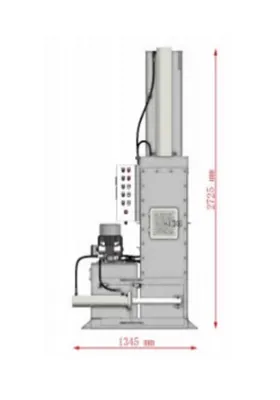

Ⅴ. SCRAP MACHINE

RZ30-4040 Vertical Aluminum Foil Briquetting Machine

Dimensional drawing of the area:

Physical display:

Material briquetting demonstration:

1. Application scope:

It is suitable for collecting, conveying and compressing the edges of production lines such as aluminum foil meal boxes and tin boxes into blocks.

2. Product features:

The system operates fully automatically, allowing direct connection to the production line. It uses air ducts to transport side materials directly to the briquetting machine for one-time compression molding, which resulting in high compression ratios and efficient molding. A a result, this process saves time by eliminating manual collection and transportation, reduces stacking space, and simplifies transportation and storage.

3. Main technical parameters:

| Parameter | Specification | Remarks |

|---|---|---|

| Pressure | 30 tons | |

| Main hydraulic cylinder | YG140/90-1000mm | RUIZHI |

| Size of downcomer | W300×H300 mm | |

| Packing size | W400×D400×H(100~300)mm | |

| Packing weight | 10-30kg | |

| Hydraulic system pressure | 16 MPa | |

| Motor power | 5.5 KW / 7.5HP | Rotational Speed 1440 r/min |

| Hydraulic Pumps | CBTt-f320F3P7 | Displacement 20 ml/r |

| Dosing method | Air Duct Charging | |

| Working method | Fully automatic | |

| Power | 3P—200V/220V/380V/400V/415V—50/60Hz | Customizable for different countries and regions |

| Hydraulic oil specifications | L—HM 46 | Ambient temperature 0~30 ℃ |

| Effective volume of fuel tank | 140L | 120kg |

| Host volume | 1350mm×1400mm×2750mm (L×W×H) | |

| Max. air delivery capacity of separator | 4241 m³/h | |

| Separator interface diameter | ≤ 150mm | |

| Weight | 1120kg (Mainframe) + 220kg (Separator) |

4. Component brand configuration

| NAME | Motor | Hydraulic Pumps | Hydraulic Valve Parts | PLC | Main Control Appliances | Limit Switch | Photoelectric Switch |

|---|---|---|---|---|---|---|---|

| Configuration | Siemens Bede | SHANGHAI VW | Hitech | Mitsubishi | Schneider | Schneider | Omron |

Cyclone paper gas separator main technical parameters

| Model Specification | Handling Air Volume (m³/h) | Air Inlet Duct | Total Weight (kg) |

|---|---|---|---|

| FLQ-80 | 4580 | 2*Φ(150-175) | 235 |

| FLQ-100 | 9560 | 3*Φ(150-175) | 275 |

| FLQ-120 | 16500 | 4*Φ(175-200) | 315 |

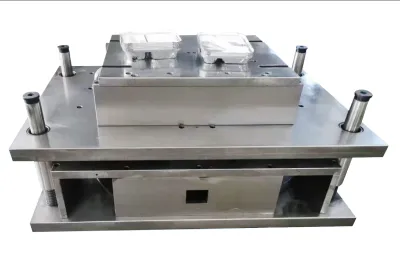

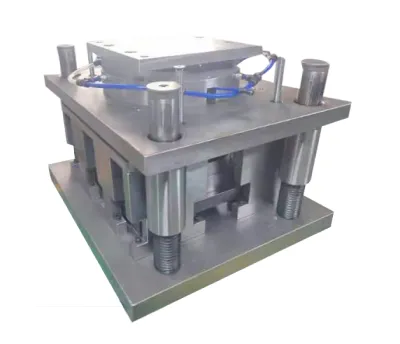

Ⅵ. MOLD

Aluminum foil lunch box with wrinkled mold

Wrinkle-free mold for aluminum foil lunch box

Aluminum foil Container mold:

Made from imported high-quality mold steel, these molds utilize gas compression rebound for enhanced flexibility, resulting in a longer service life, high precision, and stable quality. The design is optimized to match the high tensile strength of aluminum foil.

The molds range from wrinkled cost-effective molds to wrinkle-free high-end molds, each detail being meticulously planned and designed. Aluminum foil container processing is carried out in a single operation, i.e., cutting, stretching, forming, crimping, and finishing. There are edge types that molds can accommodate, e.g., G edge, L edge, IVC edge, and folded edges. Molds also may be customized to suit some customers’ requirements, with specific processes like plating or nano treatments.

Ⅶ. Manufacturer Training

Our professional trainers provide comprehensive, multi-level training to ensure that equipment operators learn fundamental operations and machine maintenance. The training is designed to help maximize the productivity of your machines and earn more profits for your factory.

| Manufacturer Training Arrangement | ||

|---|---|---|

| Training Type | Buyer factory training | Seller factory training |

| Number of Trainers | On-site operator | 2 P/TS |

| Training Period | After the installation and commissioning are completed | After the commencement of the contract |

| Training Location | Buyer factory | RUIZHI |

| Training Duration | 1 DAY | LESS THAN 5 DAYS |

| Training Content | On-site operation, maintenance training | On-site operation, maintenance training, common fault judgment and treatment |

| Training Fees | The cost of board and lodging is borne by the buyer | The travel expenses and accommodation expenses shall be borne by the buyer |

| Others | Buyers provide free work lunch | The seller provides free work lunch. Before the training, make an appointment with the seller |

Ⅷ. Equipment Recommendation Oil and Fat Meter

| Application Area | Name | Capacity | Brand | Factory Recommend |

Remark | |

|---|---|---|---|---|---|---|

| Lubrication System | Gearbox | Gear Oil | 40L | 320# | Replace in 6 months | |

| Ball Head | Hydraulic oil | 2L | 46# | Inject when the oil level is lower than the minimum liquid level line | ||

| Rail Crankshaft | Hydraulic oil | 10L | 32# | Inject when the oil level is lower than the minimum liquid level line | ||

| Overload Protection | Hydraulic oil | 3L | 32# | Inject when the oil level is lower than the minimum liquid level line | ||

| Balance Cylinder | Gear Oil | 0.5L | 68# | Inject when the oil level is lower than the minimum liquid level line | ||

Ⅸ. Equipment Customer Security Preparation Table

| NO. | Project | Require | Remark |

|---|---|---|---|

| 1 | Factory Foundation Confirmation | 1. The machine tool weighs about 12 tons, and the ground requires flat, no depression, and strong foundation 2. There is no shift and vibration during the operation of the punch, and the vibration is not easy to be too large. 3. The machine must use a horizontal instrument to test before use it |

|

| 2 | Entry – Wire Source Cable Preparation | Cable YJV 5*16 mm² | |

| 3 | Preparation for Compressed Air Access | Air source filtration accuracy 100μm Tracheal diameter 12 mm |

|

| 4 | Equipment Oil | For details, please refer to “Recommended oil and fat meter” | |

| 5 | Confirmation of Transportation Situation | 1. Confirm the transportation method according to the factory and surrounding road conditions 2. Meet the net transport size of the maximum component of the machine tool 3. Confirm the hanging method according to the actual high situation of the plant |

|

| 6 | Install a Piano Preparation | Steel rope, load-bearing more than 15 tons |

Ⅹ. General Requirements and Installation and Debugging Equipment

1. General requirements for equipment

1.1 Equipment Environmental Requirements

To maintain stability, ambient temperature must be kept constant. The required ambient temperature is 10°C to 40°C. Relative humidity at 20°C should be 40-75%.

1.2 Power Supply Voltage

3-phase, 380V

Voltage fluctuation must be within ±10%, power frequency 50Hz.

1.3 Voltage Stability

In case of unstable local voltage, the machine should be equipped with a voltage stabilizer to maintain its normal operation.

1.4 Grounding Requirements

The equipment should be properly earthed, using a minimum of 10mm² copper wire. The earth resistance should be less than 4 ohms.

1.5 Air Supply Requirements

To ensure the proper working of the equipment, the air supply should be of necessary standards. If the air quality is not proper, an air purification system (dehumidification, oil removal, and filtration) should be installed before the equipment.

1.6 Equipment Placement

To ensure optimal performance, the equipment should be placed away from direct sunlight, radiation sources, high-frequency electric motors, welding, and other equipment that might cause faults or affect machine accuracy.

2. Equipment installation and debugging

2.1 Equipment Delivery and Notification

After the equipment arrives at the user’s site, the buyer is responsible for the machine tool’s foundation, unloading, and setup. The seller must be notified promptly, and the seller will send installation and debugging staff to the site within seven days of receiving the notice.

2.2 Packaging and Missing Items

The seller and buyer will jointly open the packaging on-site (or the seller may entrust someone). If the outer packaging is intact but items are missing when opened, the seller will be responsible. The seller must promptly issue replacements, and the seller will bear the freight costs.

2.3 Preparation and Cooperation

The buyer shall finish the installation of the machine tool, i.e., provide power and compressed air to the machine, but power and gas supply shall not be started until it is properly authorized. Auxiliary supplies like oil, coolant, and lubricants shall be provided by the buyer. As the best machine supplier from China, the seller will take care of checking, installation, debugging, and final acceptance on-site, with the buyer’s full cooperation.

Ⅺ. OTHERS

1. Any matters not covered by this agreement will be resolved through negotiation between both parties.

2. This agreement is considered an attachment to the contract and will take effect simultaneously with the contract after being signed by both parties A and B.

3. This agreement is made in two copies, with one copy held by Party A and one copy held by Party B.

Ⅻ. Quality Assurance

1. The quality guarantee period is 12 months from the date of acceptance.

2. If the equipment is used under normal conditions and as instructed during the warranty period, the seller will be responsible for any damages caused by design or manufacturing defects. In case there is a fault within the guarantee period, it will be rectified or replaced by the seller. If the buyer does not rectify the issue with the seller’s instruction and system description, the seller will send a maintenance engineer to the buyer’s premises within 2 working days at no charge.

3. During the warranty period, free maintenance and replacement of spare parts will be provided by the seller. However, if the breakdown is due to the buyer’s improper operation, self-repairing, modification, or extended storage time, the buyer will be responsible for the cost of maintenance.

4. After the warranty period, the seller will continue to offer free online technical support and service. The seller will offer spare parts to Party A at preferential prices. If on-site service is required, the buyer will cover the costs based on the seller’s standard rates.

XIII. After -sales service commitment:

★ After equipment installation and debugging at the customer’s location, the company will offer safety operation training and education to ensure proper use.

★ Upon receiving a failure notice, the company will conduct telephone follow-up or online contact within 30 minutes. If these channels fail to resolve the issue, both parties shall meet and discuss further to find a solution.

★ The company’s customer service department will inspect the client facility within 2 months to analyze and correct any issues caused by the real operations, warranting and the equipment.

FAQs about Aluminium Foil Container Making Machine

- What is the production capacity of the machine?

The output rate may vary depending on the model and mold configuration. One-cavity molds produce smaller quantities of containers per cycle than multi-cavity molds that can increase production by dozens of times. Normally, 30-80 containers are manufactured per minute. - Can the machine be adjusted according to different designs of containers?

Yes, our machines do support customization. We can manufacture and create molds based on your specific container forms, sizes, and edge designs, for instance, G edge, L edge, IVC, or folded edge. - What is the raw material that this machine can accept?

The machine can take in aluminum foil rolls of different thicknesses, normally between 0.03mm and 0.15mm. The foil should have good elongation properties for efficient forming. - How long is the warranty?

A 12-month guarantee of acceptance is what we provide. Free replacements for manufacturing defects are offered within this period. - Is there technical support and spare parts available post-warranty?

Yes, we have lifetime online technical support. Spare parts can be obtained at competitive prices and on-site service provided if needed. - What utilities and factory conditions are required to install this machine?

The machine generally needs 3‑phase electrical power (380 V ±10%, 50 Hz), proper grounding, compressed air supply ≥0.55 MPa, a flat solid foundation, and sufficient space for feeding and stacking operations. - How easy is it to change moulds and adjust production settings?

Mould changes and production adjustments require some mechanical tools and setup time. Multi‑cavity moulds and different container sizes can be swapped, but proper training and setup procedures are recommended to ensure accuracy and safety.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province

![Quotation of KN-700-3-zhongyuan (2)[1] – Protected View – Word 5_7_2025 6_05_29 PM wooden edge Banding Machine](https://kingslermachinery.com/wp-content/uploads/elementor/thumbs/Quotation-of-KN-700-3-zhongyuan-21-Protected-View-Word-5_7_2025-6_05_29-PM-r5gj8x6mlcns5job2eicr7vehl5z7tp71a6xb9ijk8.png)