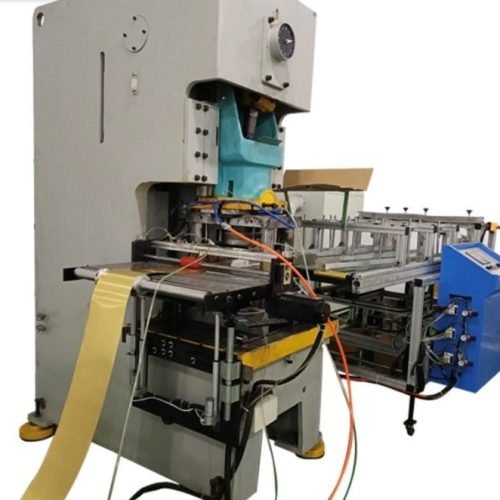

TB-1350 on-line coating machine

|

Payment Terms |

L/C, T/T at sight |

Power |

|---|---|

|

Voltage |

|

|

Stroke |

|

|

Area |

Product Description

The TB-1350 On-line Coating Machine is a superb solution developed for businesses that require precise, rapid, and flexible coating processes. It can coat multiple substrates, such as PET, PS, and PP, including those treated with silicone oil (or anti-fog agents) and anti-static coatings, and can handle substrate thickness from 0.1mm to 1.5mm with ease. The TB-1350 consistently provides a smooth, even coating on a wide variety of substrates. Whether your mission is to make products on-demand or the quality control, the TB-1350 was designed to keep up with fast, reliable output.

Main Technical Parameters

| S.N. | Parameters | Description |

| 1 | Applicable substrates | It can coat multiple substrates like PET, PS, PP, scratch-resistant, and permanent

anti-static liquid, silicone oil, anti-fog agent, etc 0.1-1.5MM |

| 2 | Synchronous control of the whole machine | 3 motors, synchronous control |

| 3 | Limited coating machine area | 1350MM |

| 4 | Coating method | Anilox |

| 5 | Mechanical line speed | 50 meters/minute |

| 6 | Production line speed | 1m/-45m per minute, depending on the

production process |

| 7 | Drying heat source type | About 108kw |

| 8 | Total heating power | About 90kw |

| 9 | 6 UV lamps with water cooling and air cooling,

stepless speed regulation high-frequency square wave UV power supply |

About 90kw |

| 10 | Total heating power of silicone oil | 32kw |

| 11 | Total power | About 210kw |

Ⅰ. Coating Unit

- Coating roller: The online coating machine uses anilox rollers with diameters of between 120 to 200 mm. There are six total rollers, and the system has a maximum coating width of 1350 mm using the main coating, presenting a smooth finish with no traces after the main coat, consistent with the sheet material.

- Coating rotation servo motor: has two servo motors rated at 2.2 kW, providing a stable and efficient coating rotation.

- Anilox pressure roller: Two pressure rollers with dimensions of Ø80 mm × 1450 mm.

- Vertical lifting pressure roller: The Pressure roller has a vertical lift well supported by 1 set of pneumatic actuators, for a smooth lifting.

- Glue tank: it is an overflow type, made of stainless steel, with a handwheel for height adjustment, and a bottom valve for quick drainage. locations were designed to be cleaned easily, installed easily, and disassembled easily. It also has an automatic circulation device.

- Scraper holder: has manual adjustment and pneumatic pressure release, it uses a cylinder with Ø50 mm × 25 mm stroke.

- Adjustable scraper angle: The scraper angle can be set freely and has a vertical lift adjustment of 200 mm.

- Worm gearbox: The scraper has a worm gearbox and allows the +5mm free movement.

- Coating the head wall panel: A3 material with strength and protection.

Ⅱ. Traction Unit

- Traction Roller: Ø200mm × 1450mm

- Pressure Roller: Ø160mm × 1450mm nitrile rubber (resistant to solvents and temperature) with Shore hardness 65, powered by Ø100mm × 75mm cylinder, adjustable pressure

- Servo Motor: 2.3KW with spiral bevel gear reducer with a ratio of 15:1

- Frame Wall Panel: channel steel A3 plate

Ⅲ. Double-layer Drying Unit

- Structure: 6M length, row combination, 3 layers, 4 drying sections plus silicone oil.

- Oven Inner/Outer Material: Inner cavity: stainless steel (0.8mm); Outer: A3 sheet steel.

- Hot Air Box: Slit nozzle type, nozzle distance 375mm, nozzle gap: 30mm and 0.8mm.

- Heating System: Electric, 32KW for each section, U-shaped stainless heating pipes, 12KW each.

- Max Temp: max 130°C, automatically entered by 4 temperature controllers.

- Air Flow: 5 AC3KW centrifugal fan + 4 frequency converters, wind speed > 4m/s with the internal hot air circulation system.

- Exhaust System: 2 centrifugal fan, 1.5KW.

- Oven Lifting: 2 air-top type air cylinders, 80×400.

- Insulation: High density asbestos, 50mm thick (oven walls), 30-40mm thick (oven doors).

- Guide Union: Ø80×1400 and Ø120×1400.

- Cooling Rollers: 2 water cooling rollers at oven outlet, Ø200×1450.

Ⅳ. Machine Color and Direction

- Color: According to user requirements, resin matte paint is used.

- Direction: According to user requirements

V. Other Configurations

| S.N. | Name | Specifications | Quantity | Brand |

| 1 | Coating machine Motor | Servo Motor: 2.3KW | 2 | Shenzhen |

| 2 | Guide wheel | Guide Roller of the

Whole Machine |

1 set | Dongtai |

| 3 | Pneumatic Components | Whole Machine | 1 set | Domestic |

| 4 | Heating Fan | 3KW | 5 sets | Ruian

Fangyuan |

| 5 | Frequency Converter | 6 sets | Shenzhen | |

| 6 | Temperature Controller | 5 sets | Domestic | |

| 7 | Exhaust Fan | 1.5KW | 2 sets | |

| 8 | Bearing | 1 set | Imported | |

| 9 | Heating Tube | Heating per Section | ||

| 10 | 6 UV Lamps | 2 sets | Zhongshan

Guangzhou |

|

| 11 | Electrical

Components and Instruments |

1 set | Chint | |

| 12 | Touch Screen (10.5 inches, Color) | 1 piece | Shenzhen

Weichuang |

|

| 13 | Thyristor | Servo Motor: 2.3KW | 5 pieces | |

| 14 | Traction | Shenzhen | ||

| 15 | PLC | Shenzhen

Weichuang |

Annex 1: Buyer’s Responsibilities

The buyer will arrange the following items and activities:

- Exhaust Pipe – Structure and all supports installed externally to the system

- Electrical Wiring – From the power distribution room to the control box on the machine

- Lighting Wiring – Indicates the installation of wiring for public area lighting fixture

- Grounding – Grounding the online coating machine for safe operation

Annex 2: Seller’s Responsibilities

The seller will provide the project delivery and support to the following items:

- Installation & Debugging

- On-site installation and equipment placement for the current system

- Training of Operating Personnel

- Training of the Buyer’s team to operate and handle the machinery

- Included Documents, Accessories, and Spare Parts

- Inverter instruction manual

- Full machine schematic diagram

- Drawings for mesh rolls

- Scraping Blade (100m)

- Warranty

- 12-month warranty from the date of delivery

- Covers any failure or defect in the machine or electrical systems with normal use

- Quality Assurance

- Manufacturing of the machine based on the Buyer’s approved structural drawings

- The Buyer’s technician will inspect and approve the equipment on-site before delivery.

- After equipment is delivered, the Buyer is responsible for other non-qualitative changes.

Conclusion

The TB-1350 Online Coating Machine combines advanced engineering with accurate control and real-world design to meet the coating needs of today’s industry. Strongly based in quality, simplicity of operation, and reliability, the TB-1350 is built to perform, whether the objective is maximizing production or improving product consistency in quality. Supported by solid support and clearly defined buyer-seller obligations, it is a machine built for today and for the future.

FAQs on coating machine

1. What substrates can the TB-1350 accommodate?

It accommodates PET, PS, PP, scratch-resistant materials, silicone oils, and many others.

2. What is the maximum width of the coating?

The maximum width of the coating is 1350 mm.

3. What is the maximum speed of the machine?

The line speed can be under 1 m and up to 45 m per minute, depending on the process.

4. What type of drying system is on the machine?

The machine is set up with electric heating drying with UV lamps.

5. Is there a warranty for TB-1350?

Yes. There is a one-year warranty provided that normal usage occurs.

6. What types of coating materials can be used?

The TB-1350 supports water-based and UV coatings depending on configuration.

7. Which substrates can be coated?

The substrates that can be coated in the TB-1350 are paper, cardboard, and packaging sheets used in printing and packaging applications.

8. Is the coating thickness adjustable?

Yes, the coating thickness of the TB-1350 on-line coating machine can be adjusted based on production requirements.

9. How does on-line coating improve efficiency?

The TB-1350 on-line coating machine from Kingsler Machinery eliminates the need for a separate coating process, reducing production time and handling.

10. Is this machine suitable for high-volume production?

Yes, the TB-1350 on-line coating machine is built for continuous operation in commercial printing and packaging facilities.

11. What kind of businesses benefit most from this machine?

The businesses that benefit the most from the TB-1350 on-line coating machine are printing houses and packaging manufacturers that require fast turnaround and consistent coating quality.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province