V Bottom Paper Bag Making Machine

|

Payment Terms |

L/C, T/T at sight |

Power |

16000W |

|---|---|

|

Voltage |

|

|

Stroke |

100-500 times/min |

|

Area |

8500*1800*1900mm |

Product Description

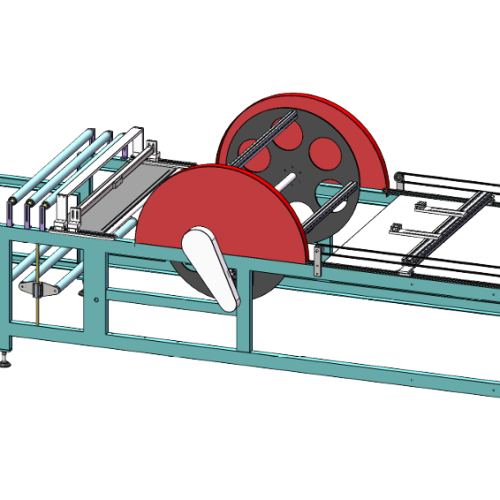

About V Bottom Paper Bag Making Machine

The V bottom paper bag making machine is an advanced automatic machine that produces paper bags from raw paper in a single process. It takes care of roll paper feeding, edge folding, tube forming, cutting, gluing, bottom folding, and finishing, managing to deliver high-speed and uniform output.

This machine is easy to operate, energy-efficient, and highly productive, making it an ideal choice for manufacturing food grade paper bags such as bread bags, KFC bags, McDonald’s bags, and other packaging solutions. With its precision engineering and automation, it minimizes labor costs while maximizing production efficiency, making it perfect for commercial and industrial bag-making applications.

We are a leading machine supply company in China, offering top-quality V Bottom Paper Bag Making Machines designed to meet the needs of businesses worldwide.

Appearance

Features of V Bottom Paper Bag Making Machine

- This machine has a touch screen interface that makes it easy to adjust settings like correction and trimming. The screen displays warnings and machine status, making it easy to use. You can switch the language to English or others for convenience.

- The machine has a simple interface, using a German-made control system that shows the real-time status of the machine.

- The machine uses a German servo motor with a long motor, making it more stable.

- The machine has a German-made color tracking system that uses accurate photoelectric technology and includes an automatic calibration function.

- The machine has a system of photoelectric sensors that automatically regulate speed, saving time on the machine configuration and reducing waste.

- This bag making machine uses a magnetic powder tension control system with automatic tension regulation, adjusting the roller diameter to maintain consistent tension.

- The machine has a pneumatic lifting system for material handling, which helps to save labor and reduces loading and unloading time.

- This machine uses the original German electrical system, ensuring stable and reliable operation with high precision, protecting users from any problems.

- The machine has a safety design with a full-face cover, which fully protects both the driver and the working environment.

MAIN TECHNICAL PARAMETERS:

| Model | HY-270 |

| Paper Thickness Range | 30-100G |

| Paper Bag Width Range | 80-270mm |

| Paper Bag Length Range | 190-650mm |

| Side Folding Range | 0-120mm |

| Production Precision | ±0.2mm |

| Machinery Speed | 100-500 pcs /min |

| Maximum Paper roll Width | 770mm |

| Maximum Paper roll Diameter | 1200mm |

| Total Power | 16 KW |

| Machine Weight | 5500KGS |

| Machine Size | 8500*1800*1900mm |

| Machine Color | White or other |

MACHINE MAIN PARTS LIST:

| 名称

Name |

数量

QTY |

产地/品牌

Standard /Brand |

| 可编程逻辑控制器

PLC |

1 | SCHNEIDER |

| 触摸屏

Touch screen |

1 | SCHNEIDER |

| 伺服电机

Puncture Servo motor |

1 | SCHNEIDER |

| 牵引伺服电机

Traction Servo motor |

1 | SCHNEIDER |

| 伺服电机

Snap Servo motor |

1 | SCHNEIDER |

| 伺服电机

Press Servo motor |

1 | SCHNEIDER |

| 伺服电机

Bottom fold Servo motor |

1 | SCHNEIDER |

| 色标跟踪光电传感器

Color mark tracking photo-sensor |

1 | Germany SICK |

| 纠边控制系统

Edge control system |

1 | PAUSOURCE |

| 磁粉制动器

Magnetic powder brake |

1 | Zhejiang |

| 气缸

Cylinder |

2 | Zhejiang |

| 成型板

Forming plate |

1 | As per customer required |

| 低压电器

Low-voltage apparatus |

1 | SCHNEIDER |

| 轴承

Bearing |

HeNan |

In-Line 4 Color Flexo Printing Machine

Control Part

- The entire machine uses microcomputer control.

- Main motor with 1.5kW inverter control for flexible speed adjustment.

- 40W reducer motor run ink separately in 4 groups

Printing Part

- Printing Part

- Pneumatic lifting and lowering of printing cylinders.

- Steel anilox roll with a chamber plastic doctor blade system.

- 360° vertical color registration with ±1mm accuracy.

- ±20mm horizontal color registration adjustment.

- Manual adjustment of ink and printing press pressure.

Drying Part

- First color drying uses a 1kW heating pipe, temperature control, and a 20W centrifugal blower for air circulation.

- Second color drying uses a 4kW heating pipe and a 0.5kW centrifugal blower for air circulation.

- A 5kW centrifugal blower is used for additional air circulation.

- Each drying oven has separate control.

Connecting Part

Pneumatic tension connects the positioner control, enabling synchronous operation between the printing machine and the bag-making machine.

Spare Parts List

| Item | Name | Original | |

| 1 | Main motor 1.5KW | China | |

| 2 | Inverter 1.5KW | China | |

| 3 | Ink running reducer motor 40W | China | |

| 4 | Low voltage control switch | Schnider | |

| 5 | Auto tension controller | Haitai | |

| 6 | Guide roller and bearing | China |

Frame Structure:

- Main motor uses synchronous drive with hard tooth gear box, and a synchronous timing belt drives each printing group.

- High accuracy planetary gearbox for 360ºcolor registration.

- Gear drive for the press printing roller (front and back printing can be switched).

- After printing, the material position is extended, allowing the ink to dry easily and the material to cool effectively.

Parameters

| Model | YT4-800 |

| Max. material width | 800mm |

| Max. printing width | 760mm |

| Printing length range | 228-1000mm |

| Max. material diameter | Ф600mm |

| Printing speed | 5-100m∕min |

| Plate thickness | As required |

PRODUCT PIC:

FAQs on V Bottom Paper Bag Making Machine

1. How does the V Bottom Paper Bag Making Machine operate?

The machine works on paper roll feeding, edge folding, tube making, cutting, gluing, and bottom folding. It finishes off the bag later with high-speed and efficient output.

2. How much does a V Bottom Paper Bag Making Machine cost?

The cost is based on machine specifications, specializations, and options. On average, it ranges from $7,000-14,500.

3. How fast is the production speed of the V Bottom Paper Bag Making Machine?

The production speed is different for different models, but all V Bottom Paper Bag Making Machines can produce 150–200 bags per minute depending on the size of the bag and the material used.

4. What is the guarantee duration of a V Bottom Paper Bag Making Machine?

Most of the machines come with a 1 to 2-year mechanical and electrical parts warranty with optional support and maintenance provided by the manufacturer.

5. Can the machine handle recycled or kraft paper?

Yes, the machine can work with different types of paper, including kraft, recycled, or coated papers, as long as the thickness is within the supported range (30–100 g).

6. What sizes of V bottom bags can it produce?

The machine can produce bags with widths from 80 mm to 270 mm and lengths from 190 mm to 650 mm, making it versatile for food, retail, and packaging applications.

7. How difficult is it to switch bag sizes or designs?

Switching sizes is straightforward with adjustable folding guides and servo-controlled mechanisms. Optional in-line printing also allows for easy design changes without stopping the machine for long periods.

8. What maintenance is required for the machine?

Regular maintenance includes lubricating moving parts, cleaning sensors, checking glue nozzles, and inspecting rollers. Proper upkeep ensures consistent speed and prevents production errors.

9. Does the machine require specialized training to operate?

Basic training is needed to operate the touch screen controls, set up the paper rolls, and monitor production. Most operators can become proficient in 1–2 days with manufacturer guidance.

Get In Touch

We’d love to hear from you! Reach out with your questions or feedback.

- +8618957999107

- support@kingslermachinery.com

- 1711, Wuyue No.1 Mansion, Jiangdong Road, Yiwu City, Jinhua, Zhejiang Province